2122

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Nº/Type of Anc.

L

fix

T

ult

τ

ault

f

eff

m

kN

kN/m

2

8 SBMA (18 units) 2.5

450–540

322-386

1

2 Conventional

7.5

960-1080

230-254

0.59-0.79

3.4

Summary

An extensive series of field anchor tests performed in different

soils showed that:

-

there is no direct proportionality between fixed anchor

length and its ultimate load capacity;

-

obtained values of the average ultimate bond stresses

in cohesive soils fit well with Ostermayer´s (1974)

diagrammatic presentation of skin friction against fixed

length, while results obtained in gravelly sands fit well

with Ostermayers and Scheele (1978) presentation of

ultimate load capacity vs. anchor length;

-

ranges of obtained efficiency factors are consistent

with tendency of values proposed by Barley (1995);

-

efficiency factor can be considered as a conceptual

control of anchor ultimate capacity;

-

fixed anchor lengths longer than 10 m do not

contribute significant beneficial effects on capacity.

-

SBMA anchors permits construction of high anchor

capacities that approach more than two times that of

the conventional anchors which utilize long inefficient

fixed length.

4

PROPOSAL FOR DESIGN METHODOLOGY

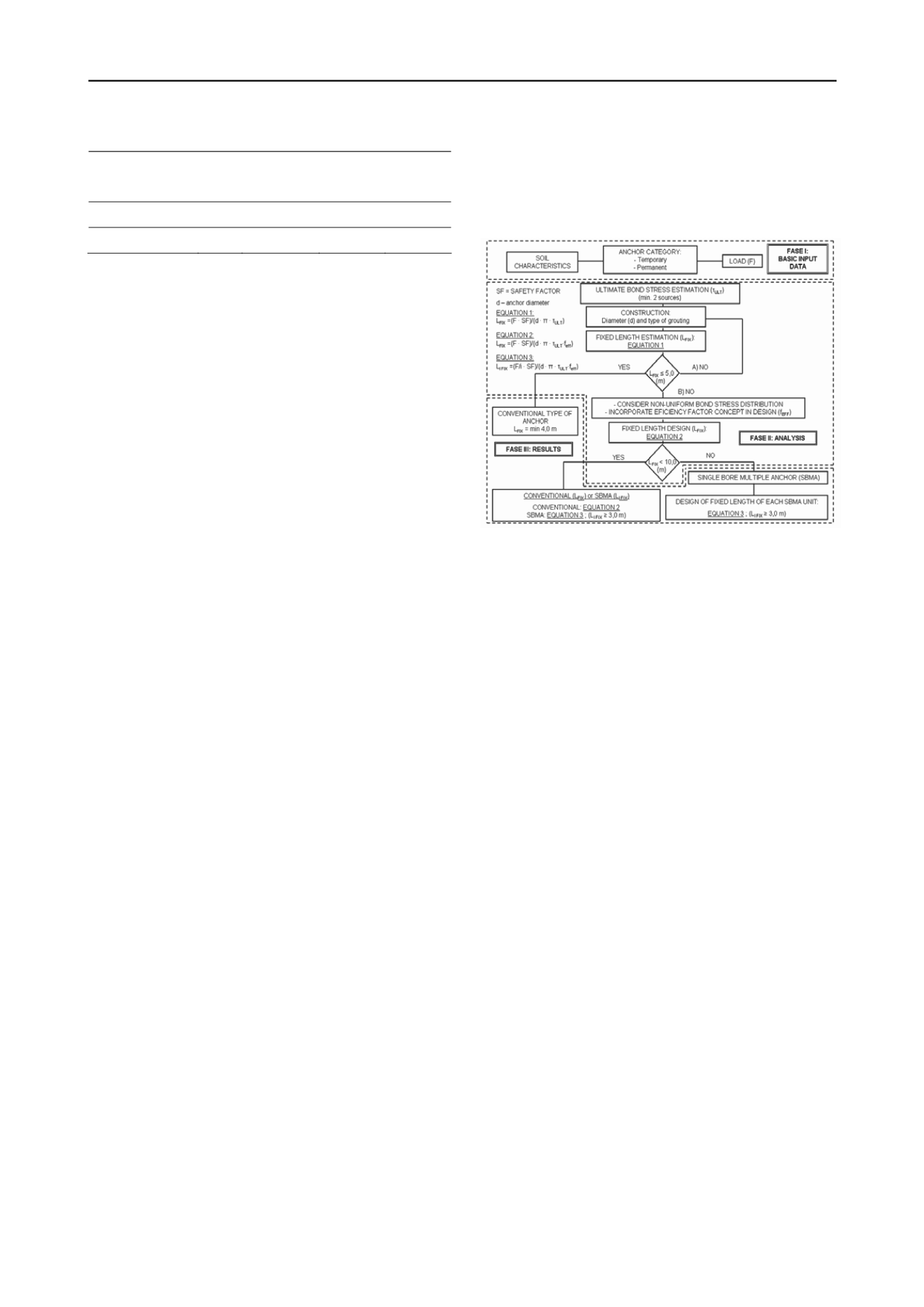

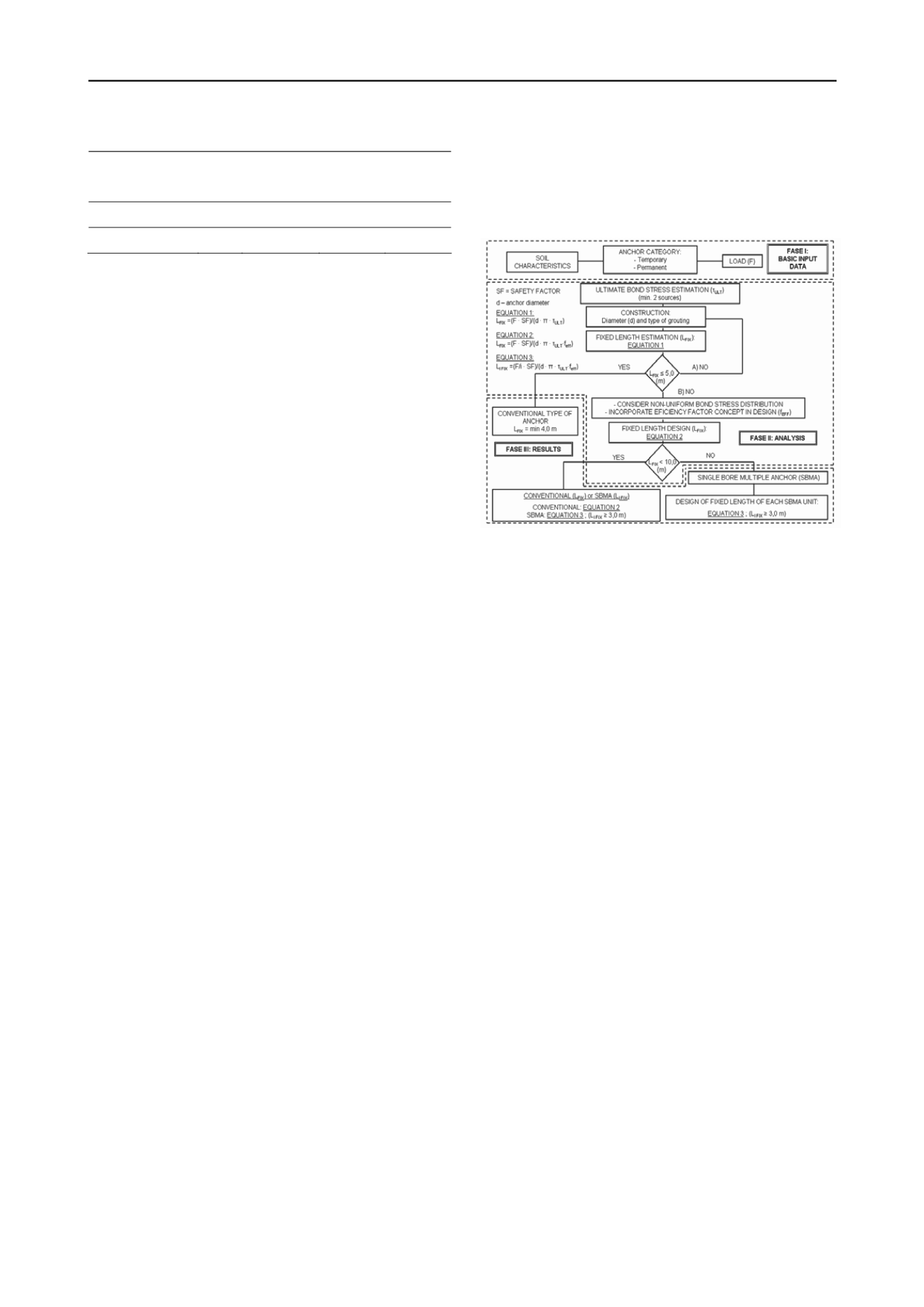

Based on the information presented in previous chapters,

proposal for design methodology for cement grouted anchors

formed by steel tendons is presented below, considering most

important parameters that define its capacity, like: soil

characteristics, execution process, ultimate and average bond

capacity, fixed length, type of anchors (conventional or SBMA),

stress distribution and efficiency factor.

Emphasis is placed on the effects of progressive debonding

that cause the non-uniform stress distribution along the fixed

length, with efficiency factor as a conceptual control of anchor

capacity. Due to the number of parameters that enter the

analysis, recommended methodology has an iterative character,

as it can be seen in Figure 6. Some of the most important steps

of the flow chart are commented below.

Phase I: Evaluation of the site subsoil conditions and

relevant properties of in situ soil and rock, as a factor that

directly influence steps in the Phase II (construction system and

skin friction estimation).

Phase II: For the skin friction estimation it is recommended

to use at least two sources, taking into account the concept or

formula that will be applied for the anchor design. If pre-design

load tests are performed to evaluate ultimate anchor load

capacity, construction process has to be exactly the same as

planned for production anchors, and fixed lengths should be

similar with test anchors.For the first iteration anchor length is

calculated considering uniform bond stress distribution

(Equation 1). If calculated fixed length is larger than 5 m,

construction process can be reconsidered (Alternative A),

varying anchor diameter or type of grouting, with objective to

reduce fixed length up to 5 m. Other option (Alternative B) is to

introduce directly the efficiency factor.

Phase III: If the fixed length obtained considering non-

uniformity is in the range between 5 and 10 m, two alternatives

are proposed. First alternative considers conventional type of

anchor, with unique fixed length unit calculated taking into

account efficiency factor (f

eff

) – Equation 2. Another alternative

is the application of SBMA. In this case fixed length of each

unit that forms SBMA is calculated considering corresponding

efficiency factor (f

eff

) – Equation 3.

If the fixed length, obtained considering non-uniformity is

greater than 10 m it is recommended to apply SBMA anchors.

Figure 6. Flow chart for design of fixed anchor length.

5

REFERENCES

Barley A.D. (1995). Theory and Practice of the Single Bore Multiple

Anchor

System. Proc. Int. Symposium Salzburg.

Balkema

Rotterdam, pp 293-301.

Barley A.D. (1997). The Single Bore Multiple Anchor System.

Proc.

Int. Conf.: Ground anchorages and anchored structures

. London,

pp. 65-75.

Barley A.D. and Windsor, C.R. (2000). Recent advances in ground

anchor and grout reinforcement technology with reference to the

development of the art.

GeoEng 2000, Int. Conf. on Geotechnical

and Geological Engineering

. Melbourne, pp. 1083-1094.

Berardi G. (1967). Sul Comportamento Deglic Ancoraggi Immersi in

Terreni Diversi.

Universidad Genoa, Inst. Contr. Sc. Serie

III (60),

pp 18-19.

Briaud J.L., Powers W.F. and Weatherby D.E. (1998). Should Grouted

Anchors Have Short Tendon Bond Length?.

Journal of Getechnical

and Geoenvironmental Engineering ASCE

, pp. 110-119.

BrS 8081 (1989). British Standard Code of Practice for Ground

Anchorages. BSI, London.

Casanovas (1989). Anchoring in rock. Elsevier Scientific Publishing

Company, pp 0-33.

Coates D.F. and Yu Y.S. (1970). Three dimensional stress distribution

around a cylindrical hole and anchor.

Proc. of 2 Int. Conf. on Rock

Mechanics

. Belgrade, pp. 175-182.

EN 1537 European Standrad (2010). Execution of special geotechnical

work – Ground Anchors.

Mesci J. (1997). Some Practical and Theoretical Aspects of Grouted

Soil Anchors.

Proc. of Int. Conf. Ground Anchorages and

Anchorages Structures

. London, pp. 119-130.

Muller H. (1966). Erfhnungenmit Verakurungen System BBRV in Fels-

und Lock-ergensteinen.

Schweisezerische Bauzeitung

, 84 (4), pp.

77-82.

Ostermayer H. (1974). Construction carrying behavior and creep

characterics of ground anchors.

Int. Conf. On Diaphragm Walls and

Anchorages. I.C.E.

London, Septiembre 18-20, pp. 141-151.

Ostermayer H. and Scheele F. (1977). Research and Ground Anchors in

Non-Cohesive Soils.

Géotechnique

3, pp. 92-97.

Weerasinghe R.B. (1993). The Behaviour of Anchorages in Weak

Mudstone. PhD Tesis, University of Bradford.

Woods R.I. and Barkhordari K. (1997). The Influence of Bond Stress

Distribution on Ground Anchor Design.

Proc. of Int. Conf. Ground

Anchorages and Anchorages Structures

. London, pp. 55-64.