901

Technical Committee 104 /

Comité technique 104

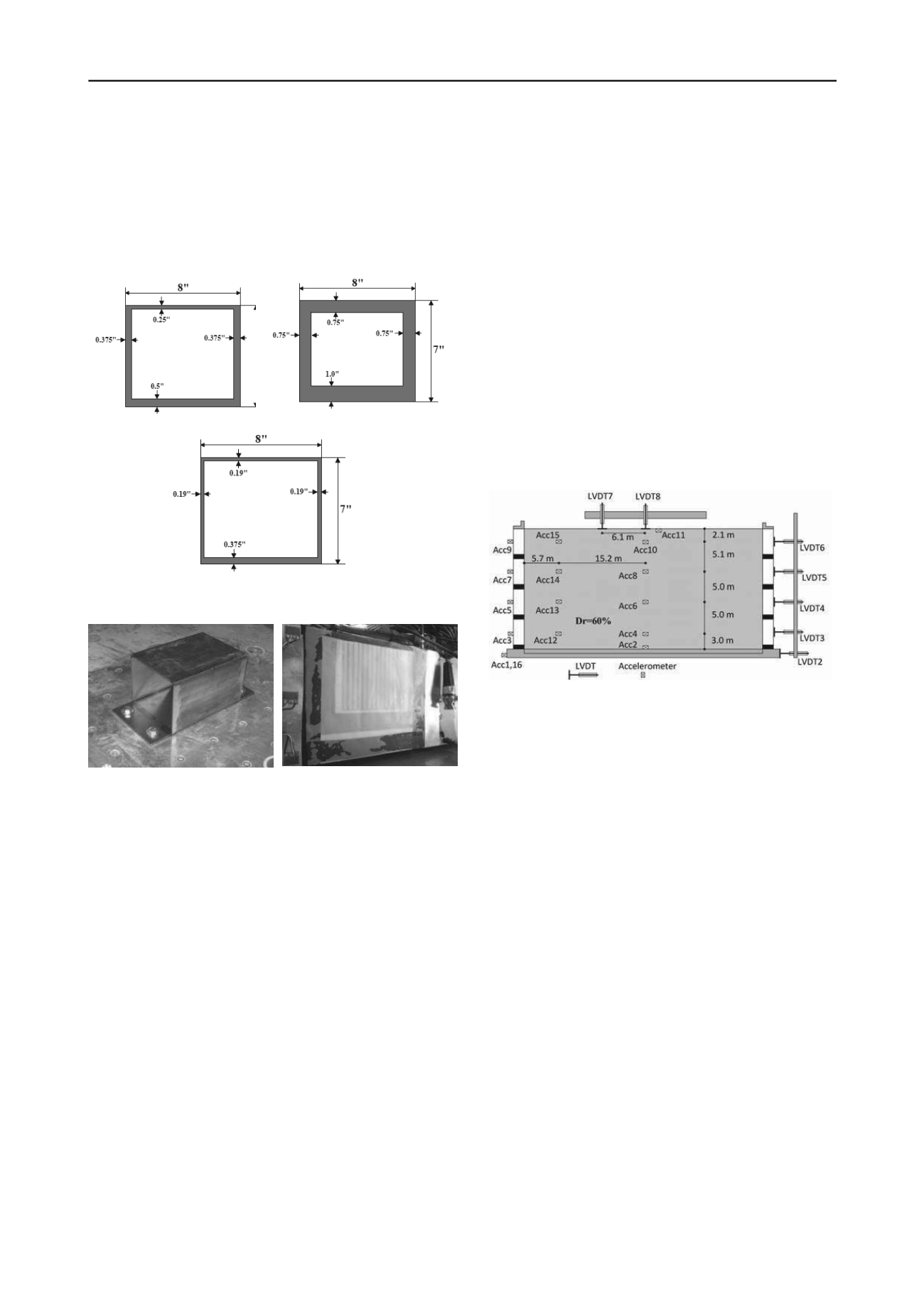

structures with a range of expected dynamic properties (e.g.,

mass and stiffness). The first mode frequency of each structural

model was measured in a 1-g shaking table test as shown in

Figure 5a. The frequency values were in good agreement with

the numerical estimates obtained using SAP and Abaqus. The

quality of the weld between the walls of models was observed

to be a key parameter in obtaining a good match between

numerical and experimental values of the resonant frequencies.

(a)

(b)

(c)

Figure 4. Dimensions of three model structures in model scale: (a) SEP

Structure; (b) Stiff SEP; (c) Flexible SEP.

(a)

(b)

Figure 5. Baseline structure: a) 1-g shake table testing; b) Tekscan

pressure sensor placement on the tunnel wall.

2.2.5

Instrumentation Challenges

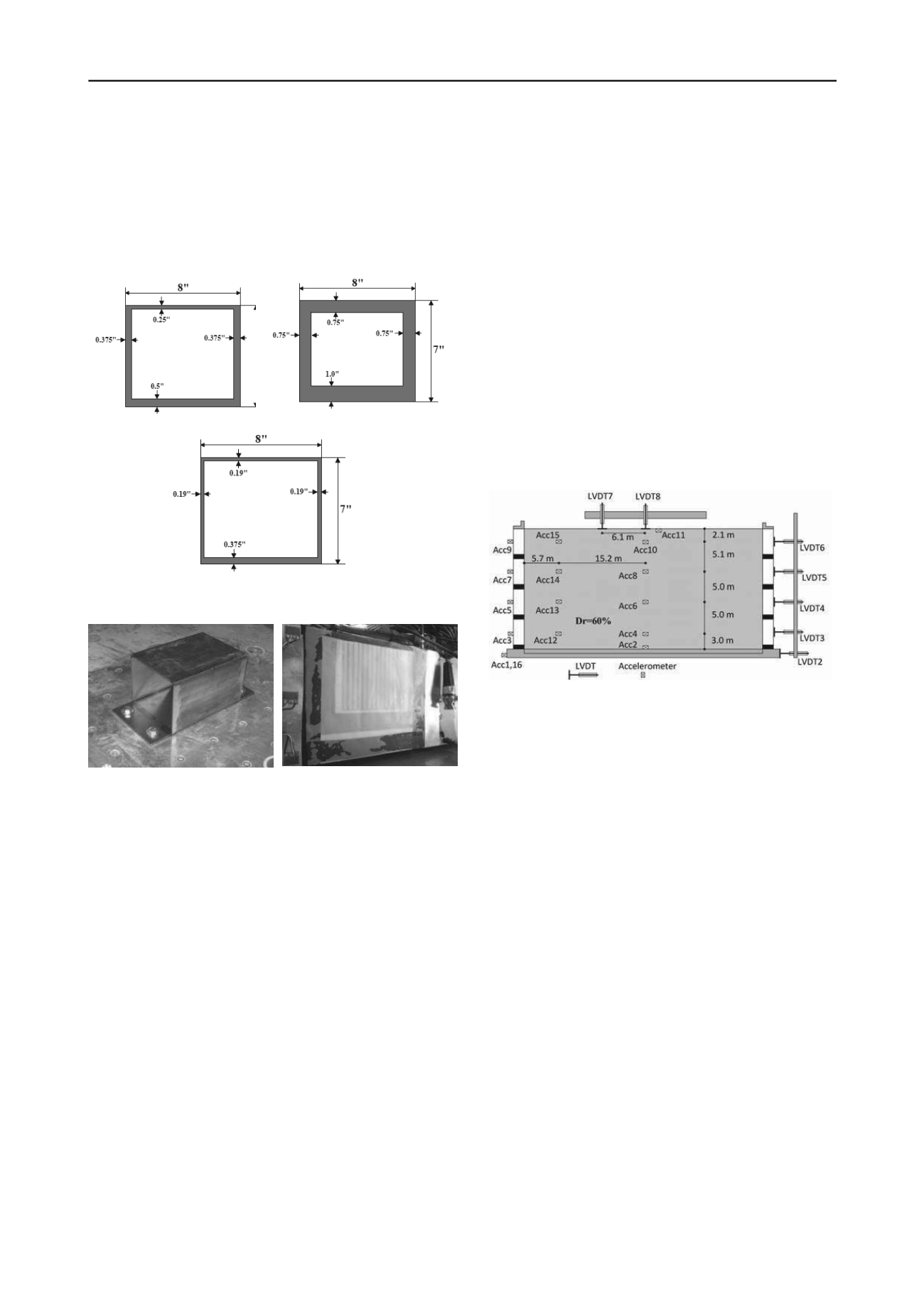

Horizontal LVDTs were mounted on a rack attached to the

stationary centrifuge platform and the light-weight cores were

attached to the container frames. Vertical LVDTs were attached

to a rack mounted on the top of the container. Permanent

racking displacement of the tunnel structures was assumed to be

small due to the high stiffness of these models. Hence,

accelerometers were judged to provide a reasonable means for

estimating transient racking deformations for each underground

structure. Visual monitoring of the structures through the

transparent walls of the container provides another means for

the verification of racking behavior during shaking.

Tactile pressure sensors from Tekscan, Inc. were used in

this study to measure dynamic earth pressures. They are

flexible, thin sheets capable of measuring normal stresses

applied with a matrix of sensels. This flexible sensor permits

measurement of 2–D stress distributions on a surface with

minimum deflection. Previous commercially-available tactile

sensors were not reliable in capturing the full amplitude content

of dynamic signals under the high-frequency environment of the

centrifuge. This is in part due to signal aliasing and the sensor’s

own frequency response (filtering effect). The sensor model

used in this study (9500) has a sampling rate up to 4,000 Hz,

which is rapid enough to avoid signal aliasing. The frequency

response of each sensors was then characterized in dynamic

tests using a load frame (Dashti et al. 2012). The frequency

recover the original pressure time histories. The response and

accuracy of these tactile pressure sensors are affected by the

presence of shear (Palmer et al. 2009). Shear was minimized by

incorporating a Teflon-Teflon interface between the sensor and

soil (Figure 5b) as recommended by Palmer et al. (2009)

response of these sensors was used as a transfer function to

PRELIMINARY FREE-FIELD TEST

e) was prepared and

3.1

Test Setup and Instrumentation

ive density of 60% was

3

A free-field soil model (with no structur

tested at 60g of spin acceleration, as the baseline experiment to

investigate the dynamic response of dry Nevada Sand and the

performance of the container when filled with sand.

A layer of Nevada sand with a relat

prepared by dry pluviation in the FSB container. The sand was

placed atop a 5 mm-thick layer of gravel, which is intended to

provide a no-slip boundary at the base of the soil profile. The

dimensions of the sand specimen were: 700 mm long, 305 mm

wide, and 336 mm high in the model scale. The instrumentation

layout within the sand layer, including LVDTs and

accelerometers, is shown in Figure 6.

Figure 6: Instrumentation layout in preliminary free-field test

3.2

Test Results

n example array of acceleration recordings

4

4.1

Test Setup and Instrumentation

EP model structure was

4.2

Test Results

Table 3 summarizes the sequence and PGA’s of the achieved

base motions during Test 1. Figure 9 compares the acceleration

(dimensions in prototype scale).

Figure 7 presents a

within the soil column and a comparison of Arias Intensity-time

histories recorded by the accelerometers in the center of the soil

profile and near the boundary of the container. The comparisons

show little difference between the two arrays, indicating

minimum boundary effects in this container. The recorded

settlement time histories at two locations were also consistent.

The settlement measurements indicated little densification

during the application of sine-sweeps, and considerable

densification during each broad-band earthquake motion.

Hence, the change in soil relative densities after each event

must be incorporated into the numerical models.

CENTRIFUGE TESTING OF SOIL-STRUCTURE

SYSTEM

A preliminary test on a trial flexible S

performed to evaluate the proposed model instrumentation and

response. The model was instrumented with accelerometers,

LVDTs, strain gauges, and pressure transducers as shown in

Figure 8. Accelerometers were placed away from, adjacent to,

and on the structure to evaluate soil-structure-interaction effects.

LVDTs were used to measure settlements at key locations.

Strain gauges were placed on both walls to measure moment

distributions and to indirectly calculate dynamic earth pressures.