1201

Technical Committee 106 /

Comité technique 106

Although resistivity provides an excellent technique for non-

intrusive measurement of the spatiotemporal variation in water

content on a large scale in the field, it can also be used to

provide localised measurements in the laboratory (e.g. Muñoz-

Castelblanc et al., 2011). The system described here has also

been adopted for use in large-scale laboratory lysimeters

(Asquith et al., 2012).

3 TIME DOMAIN REFLECTOMETRY

The TDR technique (Topp et al., 1980) is a method to measure

soil water in hydrological and geotechnical testing, by

measuring the soil bulk permittivity or dielectric constant that

determines the velocity of an electromagnetic wave transmitted

through the soil via a TDR probe (Tarantino et al., 2008). Since

the dielectric constant of water (

K

=80) is larger than air (

K

=1)

and soil constituents (

K

= 2-5), the bulk permittivity is mainly

governed by soil water content. To estimate water content from

the dielectric constant,

K

, the empirical equation of Topp et al.

(1980) is commonly used.

3.1

Coiled TDR

In geotechnical testing it would be hugely beneficial to have a

device that is capable of simultaneous measurements of soil

water content and pore water pressure at the same position. To

achieve this, a coiled TDR device was developed that could be

wound around a high suction tensiometer. The tensiometer was

developed at Durham University (Lourenço et al., 2006) and is

capable of measuring negative pore water pressures down to

-2 MPa.

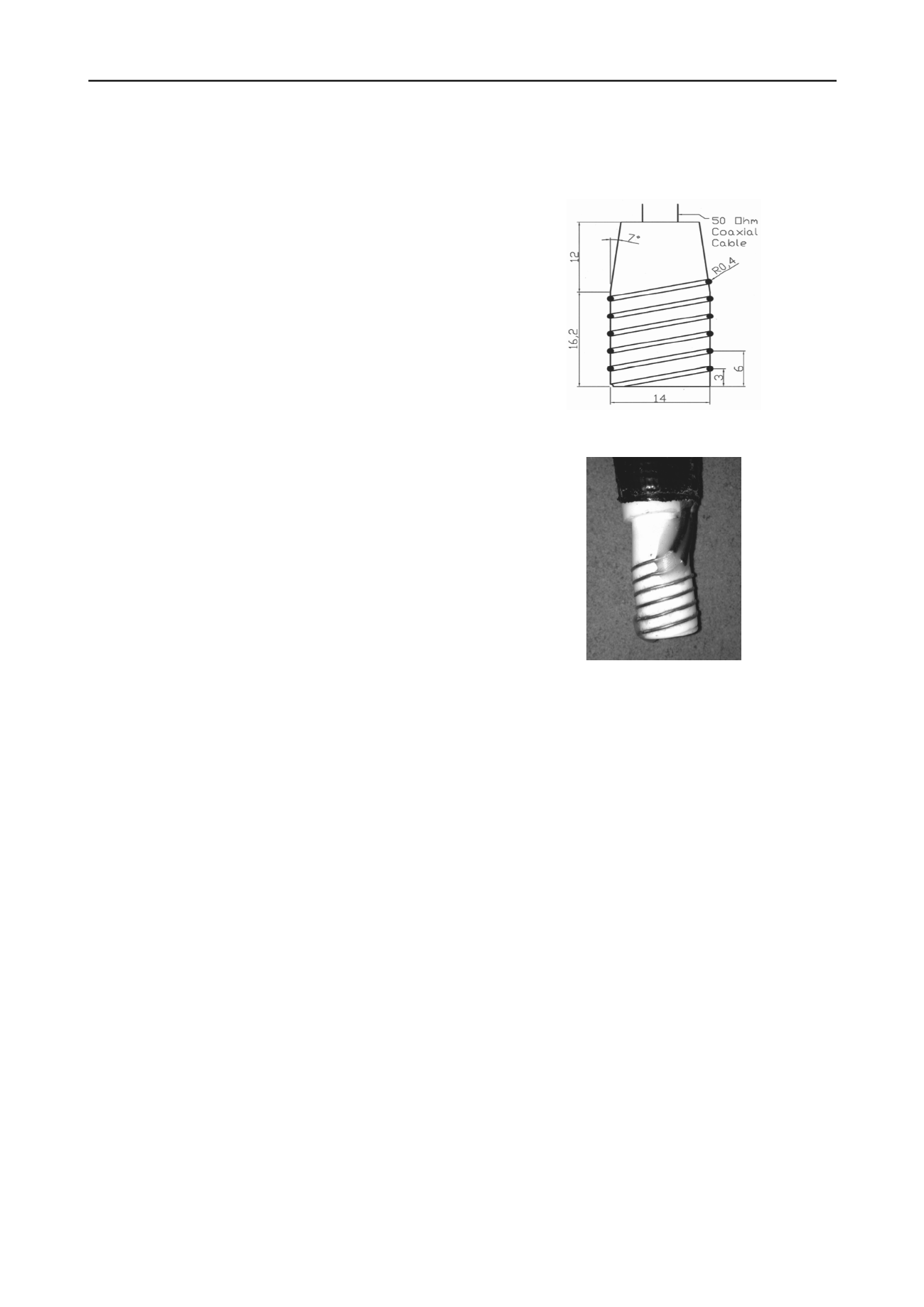

A double pronged TDR device was constructed by coiling

copper wire around the insulated stainless steel housing of the

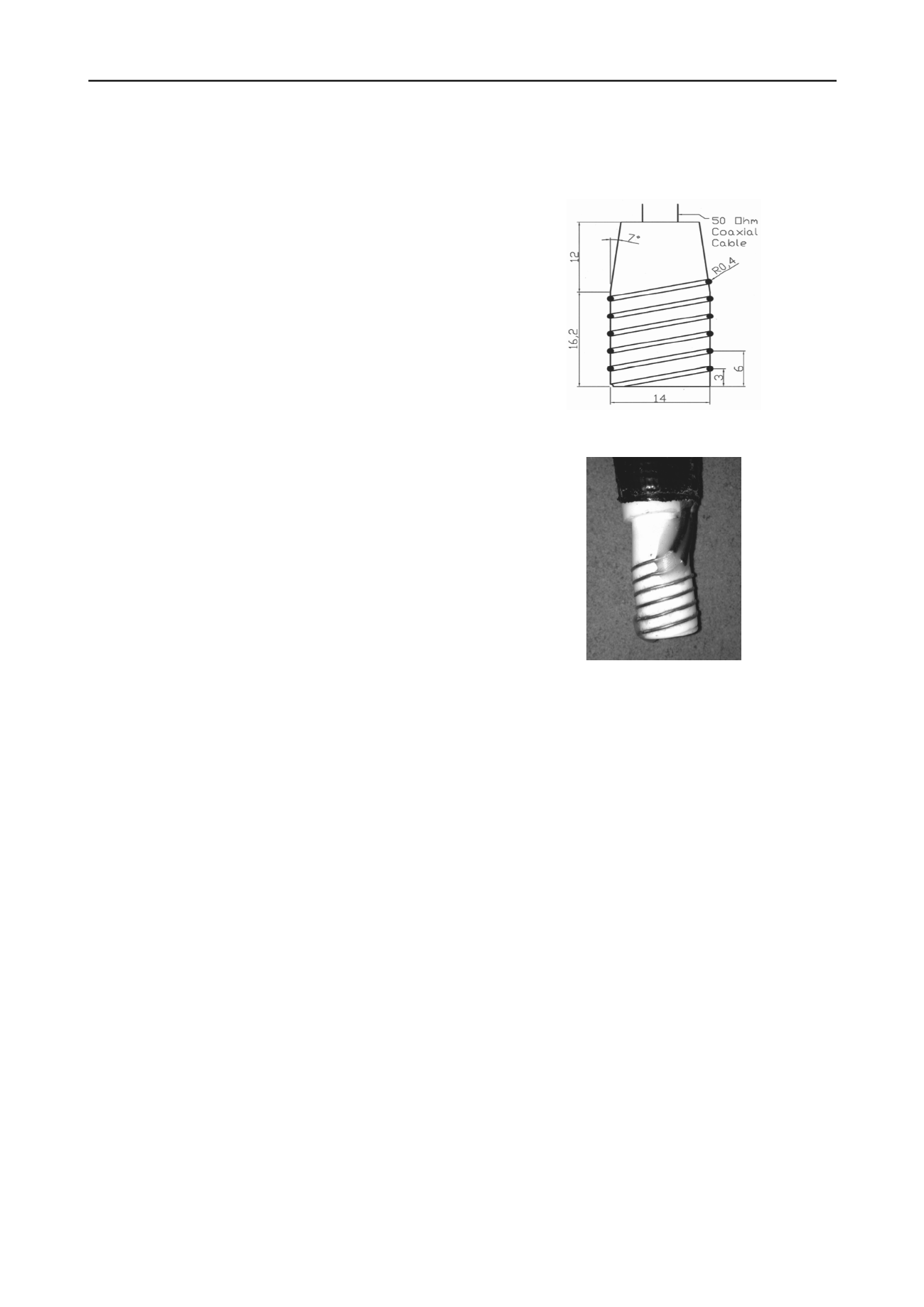

tensiometer (Figure 3). A second device was also constructed

using an impermeable ceramic tensiometer housing (Figure 4).

The ceramic chosen was an impermeable Macor machinable

glass ceramic, with a Young’s Modulus of 66.9 GPa and a

compressive strength of 345 MPa.

Each housing had two helixes (0.8 mm wide, 0.4 mm deep)

cut into them at a pitch of 6 mm. This was so that the TDR

prongs sat 3 mm apart as shown in Figure 3. This ensured that

the probe diameter to spacing ratio was within the

recommended region given by Noborio (2001) and Knight

(1992), thus promoting an even distribution of electric field

between the TDR prongs. The stainless steel body was insulated

using five coatings of an insulating varnish.

The devices were tested alongside a conventional three-

pronged TDR probe in three different soils (Leighton Buzzard

sand, Birtley Clay and a very loose organic soil) over a range of

known water contents.

The device could be simply calibrated based on the

measured dielectric constant

K

a

for known soil water contents

.

However, to better understand the effect of coiling the probe

around a steel or ceramic body and to take account of the fact

that the coiled TDR is measuring the effect of the steel or

ceramic housing that it is wound around, as well as the

properties of the soil surrounding it, a mixing model approach

(Roth et al., 1990) was investigated for interpreting the data.

The aim was to split the apparent dielectric constant

K

a

into two

parts, the dielectric constant of the tensiometer housing

K

house

and the dielectric constant of the soil

K

soil

.

Ferré et al. (1998) showed that for the special case where the

rod surface was divided equally between two materials, the

apparent dielectric constant could be described as:

K

a

= 0.5

K

1

+ 0.5

K

2

(3)

where

K

1

and

K

2

are the dielectric constants of the two

surrounding materials.

The helix which seats the TDR probe was designed so that

half of each prong was exposed to the soil. Therefore

K

1

can be

replaced by

K

house

and

K

2

by

K

soil

. By measuring

K

a

,

K

soil

was

then interpreted by rearranging eq. (3) and finding a suitable

value of

K

house

.

Figure 3. Schematic of tensiometer housing and coiled TDR

(dimensions in mm)

Figure 4. Coiled TDR constructed around a ceramic tensiometer body

The manufacturer’s specifications give the dielectric

constant of the ceramic to be 6.03 at 1 kHz and 5.67 at 8.5 GHz.

Since the TDR bandwidth extends to around 1.5 GHz, a value

of 6.0 was taken as the first approximation of

K

house

. This value,

however, still caused large underestimations of volumetric

water content,

θ

. By using trial and error and measuring the

standard deviation of the difference between the actual

dielectric constant calculated from

θ

, and

K

soil

obtained from the

mixing model, the best value of

K

house

was found to be 3.5.

This value of

K

house

for the ceramic was significantly lower

than the dielectric constant given by the manufacturer. Adopting

a

K

house

value of 6.0 would be assuming that there was a perfect

contact between the copper wire and the ceramic within the

helix. However, as the grooves cut into the ceramic were not

perfectly smooth and some tension in the prongs was lost when

gluing them in place, this could introduce a small air gap

between the copper wire and the ceramic body, changing the

effect that the housing would have on the measured result.

For the stainless steel probe, using the same approach gave

the optimal value of

K

house

to be 2.65. In the case of the stainless

steel body, the dielectric constant of the insulation was

unknown so comparisons could not be made.

The results of applying the simplified mixing model to the

data (using

K

house

as 2.65) are shown in Figure 5. It can be seen

that the results are slightly underestimated for clay and

overestimated for sand, compared to the readings obtained from

the conventional 3-prong TDR device.

It is likely that the higher values for sand are due to poor

contact with the probe. If these higher values for sand were