1288

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

–

Since the apparatus can conduct a CBR test immediately

after the freeze-thaw process without moving the sample,

the effects of the freeze-thaw action on the bearing-

capacity characteristics of unbound granular base course

materials can be examined under clear boundary condition,

as well as the initial conditions.

2.2

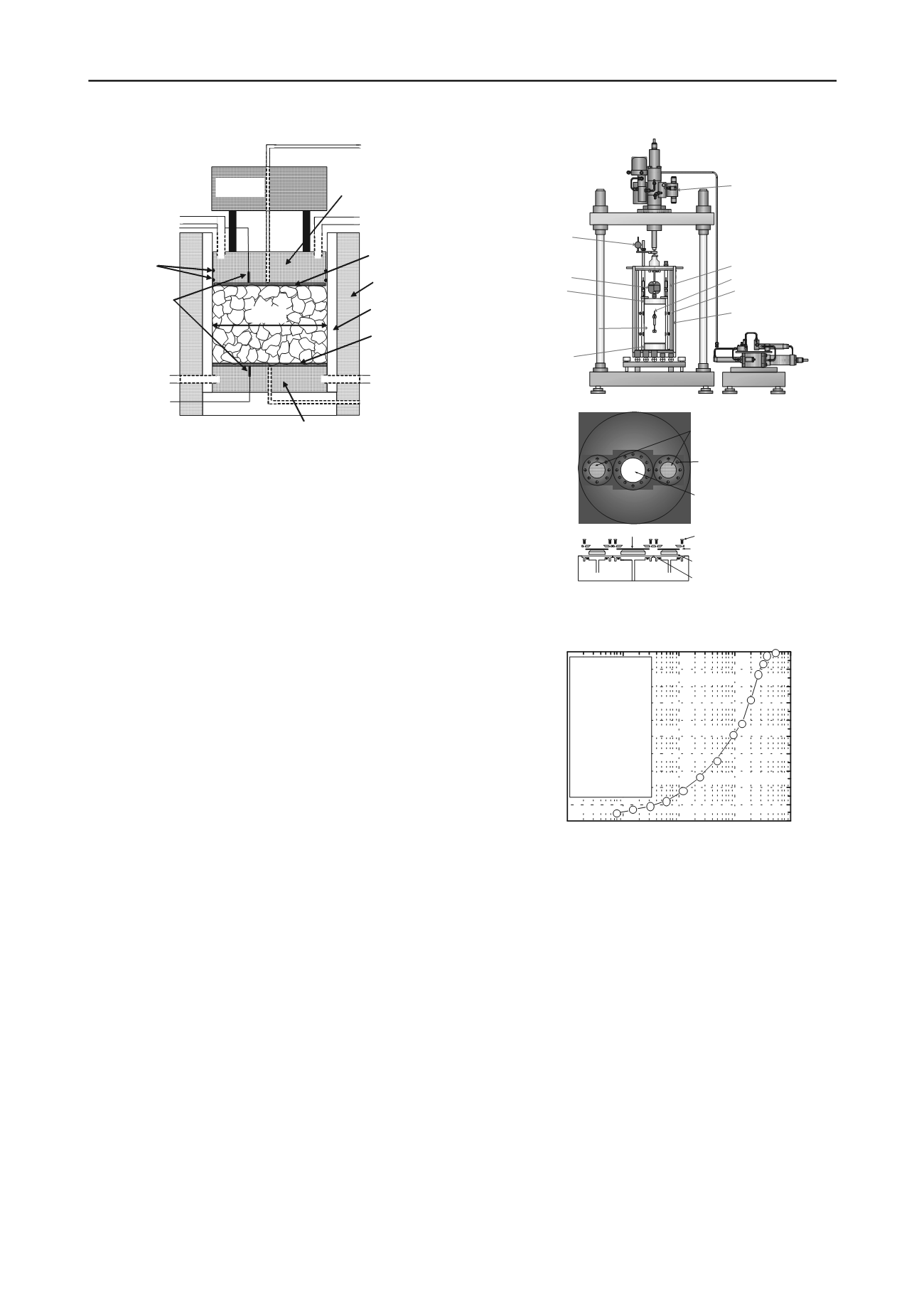

Medium-size triaxial apparatus for unsaturated soils

A schematic diagram of a medium-size triaxial apparatus for

unsaturated soils is shown in Figure 2. One key feature of the

apparatus is the structural design of the cap and pedestal as

shown in Figure 2. Here, the versapor membrane filter is a kind

of microporous membrane filters made from hydrophilic acrylic

copolymer, and polyflon filter is a hydrophobic filter made from

polytetrafluoroethylene. The other key features are as follows:

–

Since the apparatus can use a medium-size cylindrical

specimen (

�

=150mm,

H

=300mm), a triaxial compression

test can be performed in accordance with the “Standard

Method of Test for Determining the Resilient Modulus of

Soils and Aggregate Materials (AASHTO Designation:

T307-99)” (AASHTO, 2003).

–

The apparatus can apply the matric suction from both ends

of the specimen (Figure 2). Besides, pore water is allowed

to drain from both cap and pedestal. Accordingly, the

apparatus can reduce the testing time by shortening the

length of drainage path to half of the specimen height, in

addition to the effect of versapor membrane filter.

–

The apparatus can apply axial load to a specimen with high

accuracy by both strain control method and stress control

method with only one hybrid actuator. Moreover, the

apparatus can perform both monotonic loading tests with

very slow loading rate, and cyclic loading tests in which

the maximum frequency of cyclic loading is up to about 10

Hz.

3 METHODOLOGY

3.1

Method of freeze-thaw CBR test

CBR tests on the specimens exposed to different patterns of

freeze-thaw history under three different water contents were

conducted by using the newly developed freeze-thawing CBR

test apparatus. As a test sample of the CBR test, a natural

crusher-run (C-40, Figure 3) made from angular, crush, hard

andesite, which is employed at the subbase course of pavement

structures in Japan, was used. The specimen was prepared by

compacting the air-dried samples (water content,

w

=1.8%) with

a vibrator at a degree of compaction (

D

c

) of 95% (“air-dried

condition”). Then, air-dried specimens were saturated with

permeating water for 1 hour (“saturation condition”), and after

the saturation process saturated specimens were allowed to

drain by gravity for 3 hours (“wet condition”). Therefore, there

were three types of specimens defined by the difference in

initial water content.

A freeze-thaw CBR test of C-40 was conducted as follows.

Freeze-thaw of the specimen was performed according to JGS

0172-2003, though this research adopted closed-system freezing

so that the initial water content of the specimen could be

maintained. The freeze-thaw process was repeated, and the

number of freeze-thaw process cycles (

N

f

) was given in three

patterns of

N

f

=0 (no freezing), 1, and 2 cycles. After subjection

to the freeze-thaw history, CBR test was carried out as per

Japanese Industrial Standards “Test Method for the California

Bearing Ratio (CBR) of Soils in Laboratory (JIS A 1211:

2009)”.

3.2

Resilient modulus test

Cyclic loading triaxial compression tests on C-40 were

performed under three different water contents in conformance

with the AASHTO Designation: T307-99 by using the newly

developed medium-size triaxial apparatus for unsaturated soils

as follows. In the air-dried condition (

w

=1.2%), an air-dried

specimen after compaction (

D

c

=95%) was isotropically

consolidated under an effective confining pressure (

σ

c

'

) of 49.0

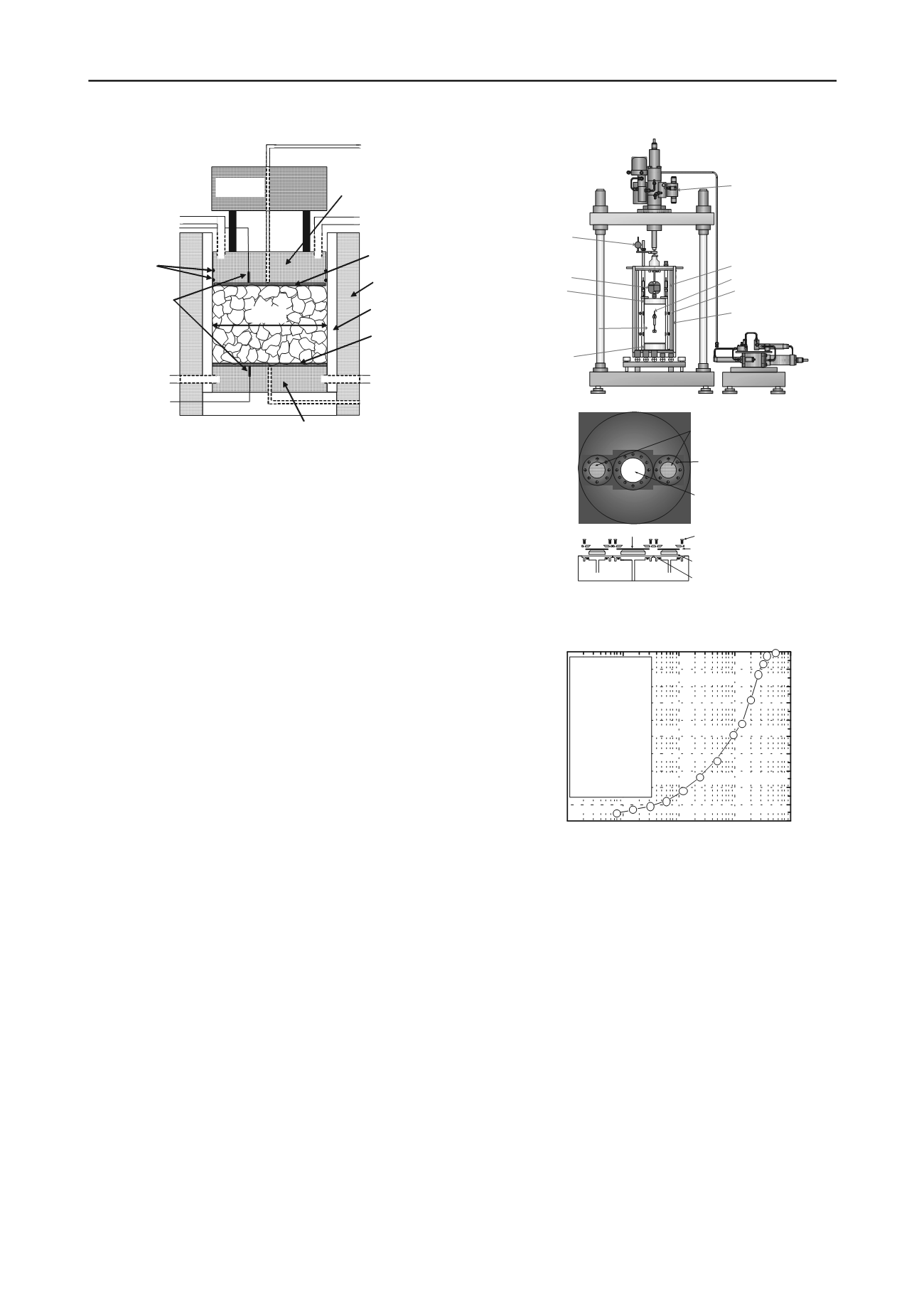

150

Surcha

rge

Water supply

/ drainage

Coolant

circulating line

Insulation

Acrylic cell

Base cooling plate

Temperature

sensor (pt100)

Porous metal

with filter paper

O-ring

Water supply

/ drainage

Porous metal

with filter paper

Top cooling plate

Coolant

circulating line

Coolant

circulating line

Coolant

circulating line

Figure 1. Freeze-thawing CBR test apparatus.

Hybrid

Actuator

Triaxial Cell

Pedestal

Cap

Gap Sensors

LVDT

Dial Gauge

Specimen

150mm x 300mm

LLVDT

Load Cell

(a)

Water

Plumbing path

(

mm)

Screw

Air supply path

(

12mm)

Polyflon filter

Screw

Versapor membrane filter

Porous metal

O-ring

Figure 2. Medium-size triaxial apparatus for unsaturated soils.

(a) Schematic diagram of test apparatus.

(b) Structural design of cap and pedestal.

0.01

0.1

1

10

100

0

10

20

30

40

50

60

70

80

90

100

C-40

D

50

= 9.1 mm

U

c

= 37.1

F

c

= 5.20

PI = NP

s

=2.74 g/cm

3

dmax

=2.07 g/cm

3

w

opt

=8.2%

Soundness = 4.6%

Percentage passing (%)

Grain size (mm)

Figure 3. Physical properties of subbase course material.

(b)