1285

Technical Committee 202 /

Comité technique 202

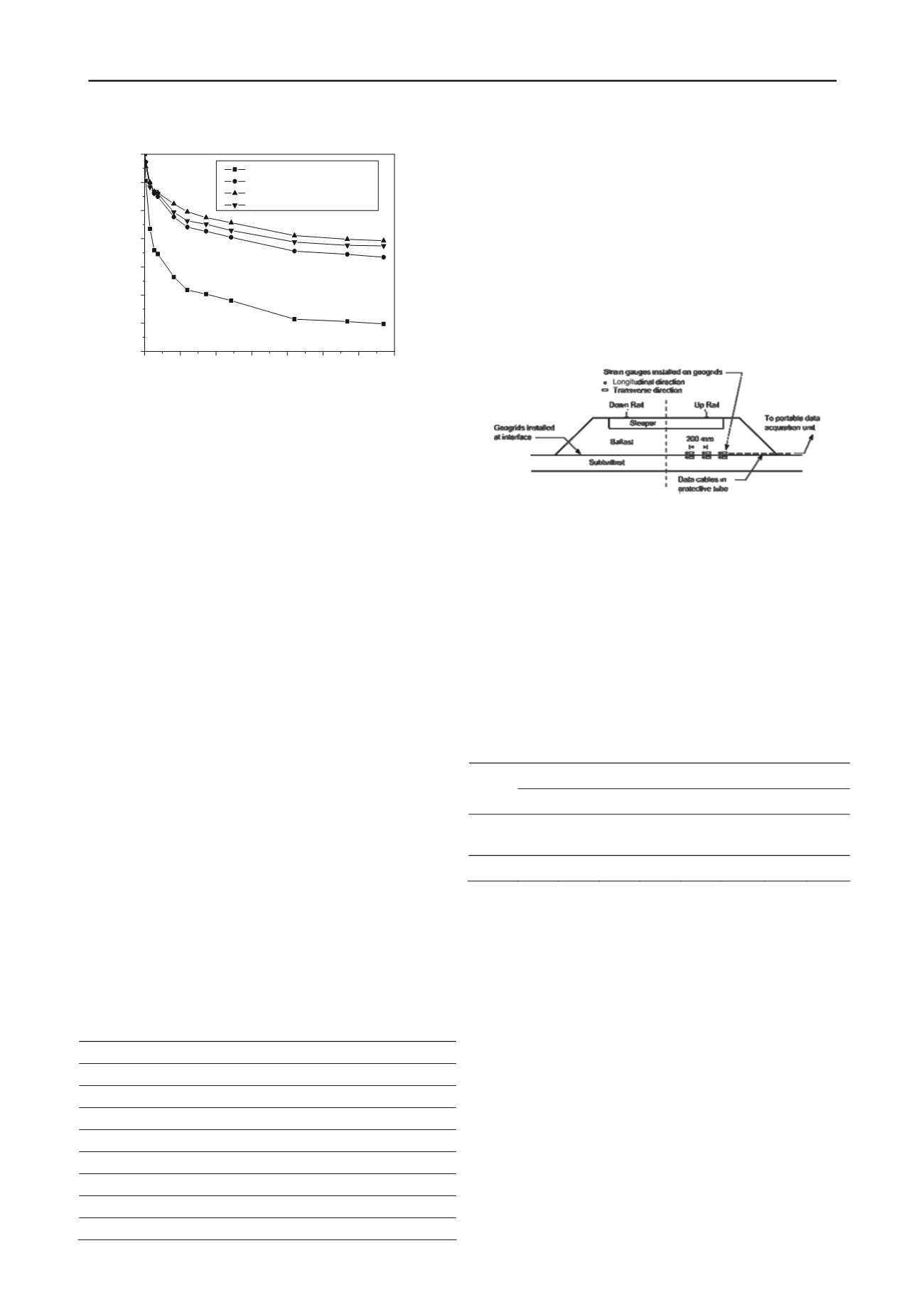

Figure 4. In-situ response of the ballast layer: lateral deformations (data

sourced from Indraratna et al. 2010).

3.3

Lateral ballast deformations

Average lateral deformations of ballast are plotted against

y high

indicate

o investigate the performance of different types of

study was also undertaken on an

instrumented track se

Singleton,

Newcastle.

4.1

Site geology and

nstruction

Nine experimental se

ere included in the trial track

while it was under con

, on three diffe

of sub-

grades, including (i) th

ely soft gener

vial

silt clay deposit (S

1-4 and Sec

the

intermediate cut siltsto

tions 5 and

C

),

he stiff

reinforced concrete bri

k supported by piled abutment

(Section B), as shown in Table 2. Further details of track

construction and material specifications c

und in

Indraratna et al. (2012c).

the number of load cycles (

N

) in Figure 4. The recycled ballast

with moderately graded particle size distribution (

C

u

= 1.8)

showed less lateral deformations compared to the very uniform

fresh ballast (

C

u

= 1.5). Recycled ballast often shows less

breakage because the individual particles are more rounded

which prevents high angular corner breakage caused b

in Figure 4

stress concentrations. The results presented

that the geocomposite reduced lateral deformation of fresh

ballast by about 49 % and that of recycled ballast by 11 %. The

apertures of the geogrid offered strong mechanical interlocking

with the ballast. The capacity of the ballast to distribute loads

was improved by the placement of the geocomposite, which

substantially reduced settlement under high repeated loading.

4 USE OF GEOSYNTHETICS FOR STABILISING A

BALLASTED TRACK: SINGLETON CASE STUDY

T

geosynthetics for improving the overall track stability under in

situ conditions, an extensive

ctions in

near the City of

track co

ctions w

struction

rent types

e relativ

ections

al fill and allu

tion

A

), (ii)

y

ne (Sec

and (iii) t

dge dec

a

an be fo

Table2. Reinforcement at experimental sections using geogrids,

geocompolistes, and shock mats.

Section

Location

Reinforcement

A

234.75

-

1

234.66

Geogrid 1

2

234.40

Geogrid 2

3

234.22

Geogrid 3

4

234.12

Geocomposite

B

232.01

4.2

Track instrumentation

Shock mat

C

228.50

-

5

228.44

Geogrid 3

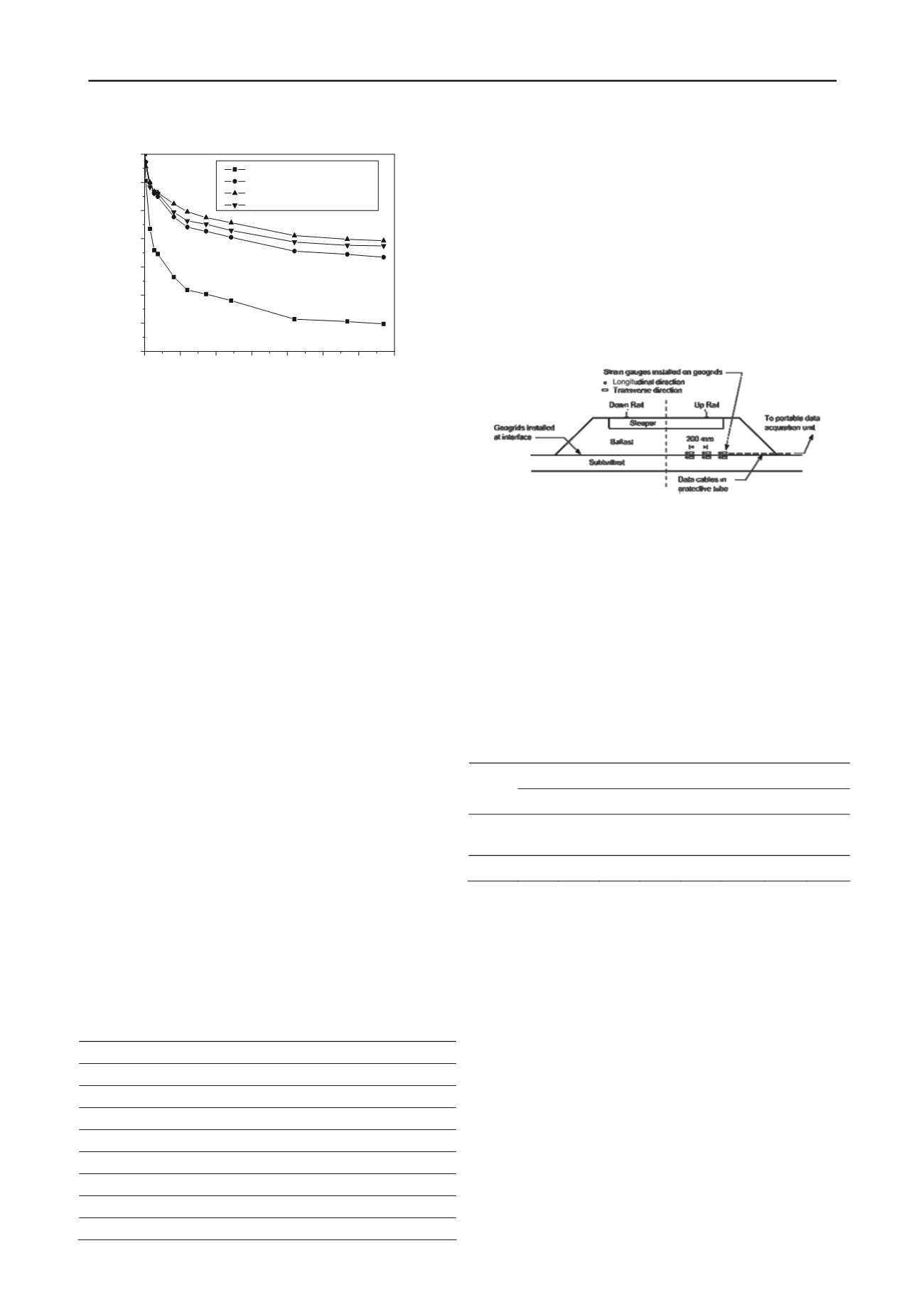

The strain gauges were installed in groups, 200 mm apart, and

ds in both longitudinal and

5.

ls o k i

me

n

str

uge

4.3

ared,

grade

ncrete

on the top and bottom sides of the gri

transverse directions (Figure 5). The strain gauges were of a

post-yield type suitable to measure strains in the range of 0.1 to

15%. Two pressure cells were installed at Sections 1, 5,

A

and

C

. At these locations, one pressure cell was installed at the

sleeper-ballast and another at the ballast-sub-ballast interface.

At Section

B

, three pressure cells were installed at the synthetic

mat-deck interface. Settlement pegs were also installed at the

sleeper-ballast and ballast-sub-ballast interfaces to measure the

vertical deformations of the ballast layer.

Figure Detai

f trac nstru ntatio using ain ga s.

Vertical ballast deformations

The settlements (

s

v

) and vertical strains (

v

) of the ballast layer

after 2.3

10

5

load cycles are reported in Table 3. The vertical

settlements of sections with reinforcement are generally smaller

than those without reinforcement. This observation is mainly

attributed to the effective interlocking between the ballast

particles and grids, thus inducing increased track confinement

as explained earlier. When sections

a

,

b

, and

c

are comp

the results indicate that

s

v

and

v

are larger when the sub

stiffness becomes smaller, i.e.

S

is smallest on the co

v

bridge deck and largest at the alluvial deposit.

Table 3. Vertical deformation and strain of ballast after 2.3

10

5

load

cycles.

Instrumented section details

1

2

3

4

5

A

B

C

S

v

(mm)

16.3

21.2

14.8

16.0

16.3

23.8

8.8

17.8

v

(%)

5.4

7.1

4.9

5.3

5.4

7.9

2.9

5.9

It is also observed that the geogrid is more effective in terms

ported by Ashmawy and

Bourdeau (1995) thorough

geogrid at

Section 3 performed better, although the tensile strength did not

differ much with the other types.

is is a

um aperture size (40 mm) which would enable better

cking between the b parti

d the rid.

4.4

Strains accumulation in

geocomposites

ins after

of reducing track settlement for relatively weak subgrades.

Similar observations have been re

full scale testing. The

Th

ttributed to the

optim

interlo

allast

cles an geog

geogrids &

Accumulated longitudinal (

l

) and transverse (

t

) stra

2.3

10

5

load cycles are given in Table 4. The transverse strains

were generally larger than the longitudinal strains, and this is

attributed to the ease of lateral spreading of the ballast layer

upon loading. It was also observed that

l

and

t

were mainly

influenced by the subgrade deformations. The strains of geogrid

at Section 4 were relatively large although its higher stiffness

could have resulted in smaller strains. This is because, the

thicker general fill underwent large lateral deformations shortly

after the track was commissioned. Induced transient strains in

both longitudinal and transverse directions due to the passage of

0

1x10

5

2x10

5

3x10

5

4x10

5

5x10

5

6x10

5

7x10

5

-14

-12

-10

-8

-6

-4

-2

-0

Average lateral deformation of ballast, (S

h

)

avg

(mm)

Fresh ballast (uniformly graded)

Recycled ballast (broadly graded)

Fresh ballast with geocomposite

Recycled ballast with geocomposite

Number of load cycles, N