1784

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The average whole life costs for the traditional method and their

upper limits differ up to 25% between subareas. The average

whole life costs for a 1 year and 2 year surcharge time are more

or less equal. The 90% upper limit is much higher for the 1 year

surcharge time, corresponding to 20 to 30% uncertainty. This

large uncertainty is due to the large uncertainty in maintenance

costs. However, the uncertainty in compression parameters and

consolidation coefficients is the fundamental cause of the

uncertainty in the whole life costs, since maintenance costs are

related to post-construction settlements. The whole life costs for

the piled embankment are much higher than for the traditional

method for this particular case. The difference mainly depends

on the length of the piles and may be smaller in other cases. The

uncertainty in whole life costs of the piled embankment is

limited to 6% and is mainly due to uncertainty in the unit costs

of construction materials.

2.9

Development Phase, second stage

A new data set with CPTs, borings and laboratory data is

obtained for part of area III. The centre-to-centre distance of the

CPTs is approximately 50 m, an increase in data density by a

factor 40. Soil profiles are interpreted directly from CPT

characteristics, and validated with the lithology observed in the

borings. The compression constants determined in laboratory

tests represent a 10% higher compressibility. The consolidation

coefficients are up to 5 times higher compared to the initial

parameter set. The variation coefficient of the new set of

compression parameters is slightly lower at 20%; the variation

in consolidation coefficients varied by a factor 2, as in the initial

parameters set.

Generally, uncertainty in the whole life costs is caused by a

combination of uncertainty in the geotechnical parameters, and

the sensitivity of the construction method to this uncertainty.

The contribution of subsoil heterogeneity to the overall

uncertainty is minor. The effects of variations between

individual soil profiles or CPTs are strongly reduced by

averaging along the road alignment.

2.7

Presentation Phase

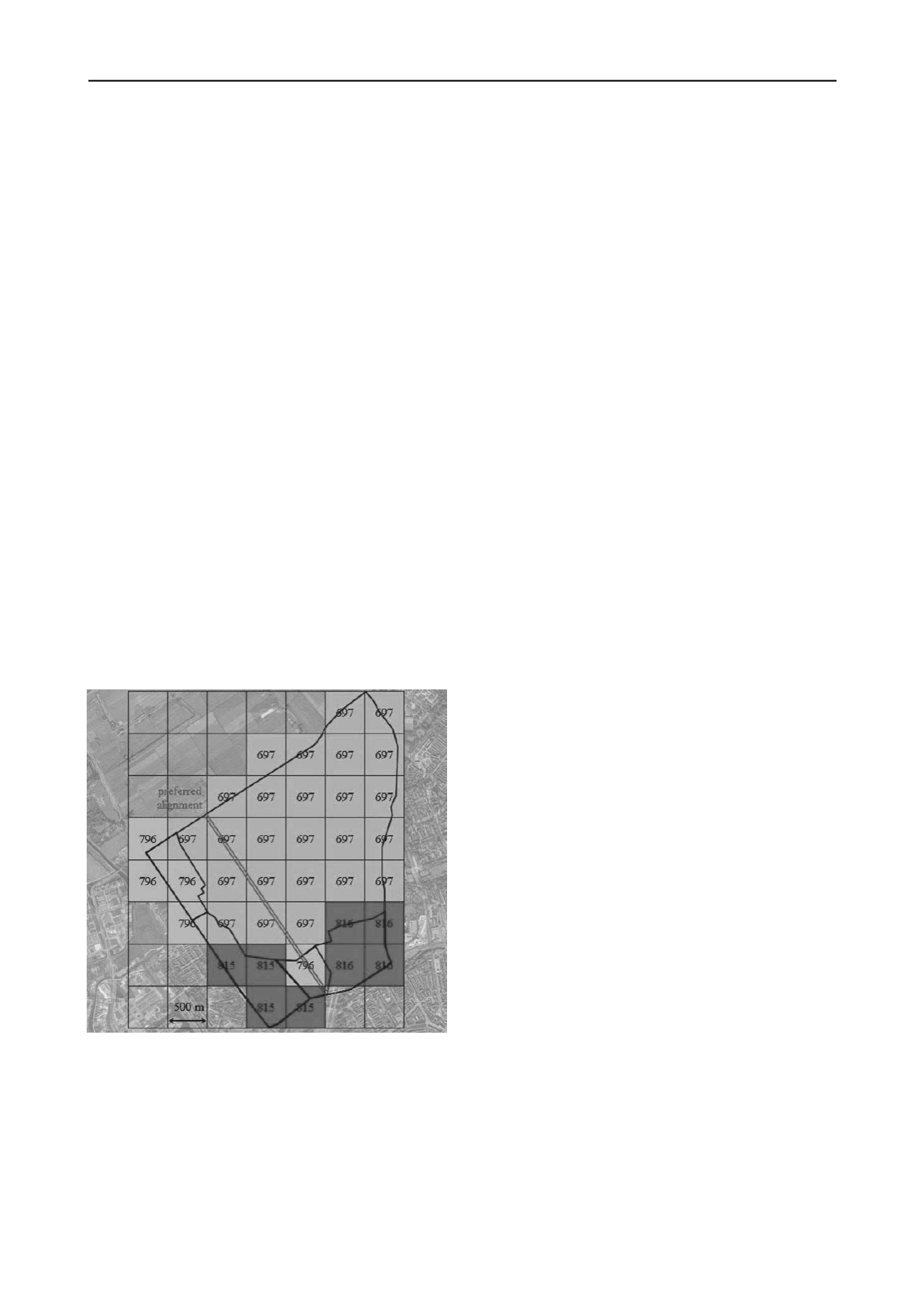

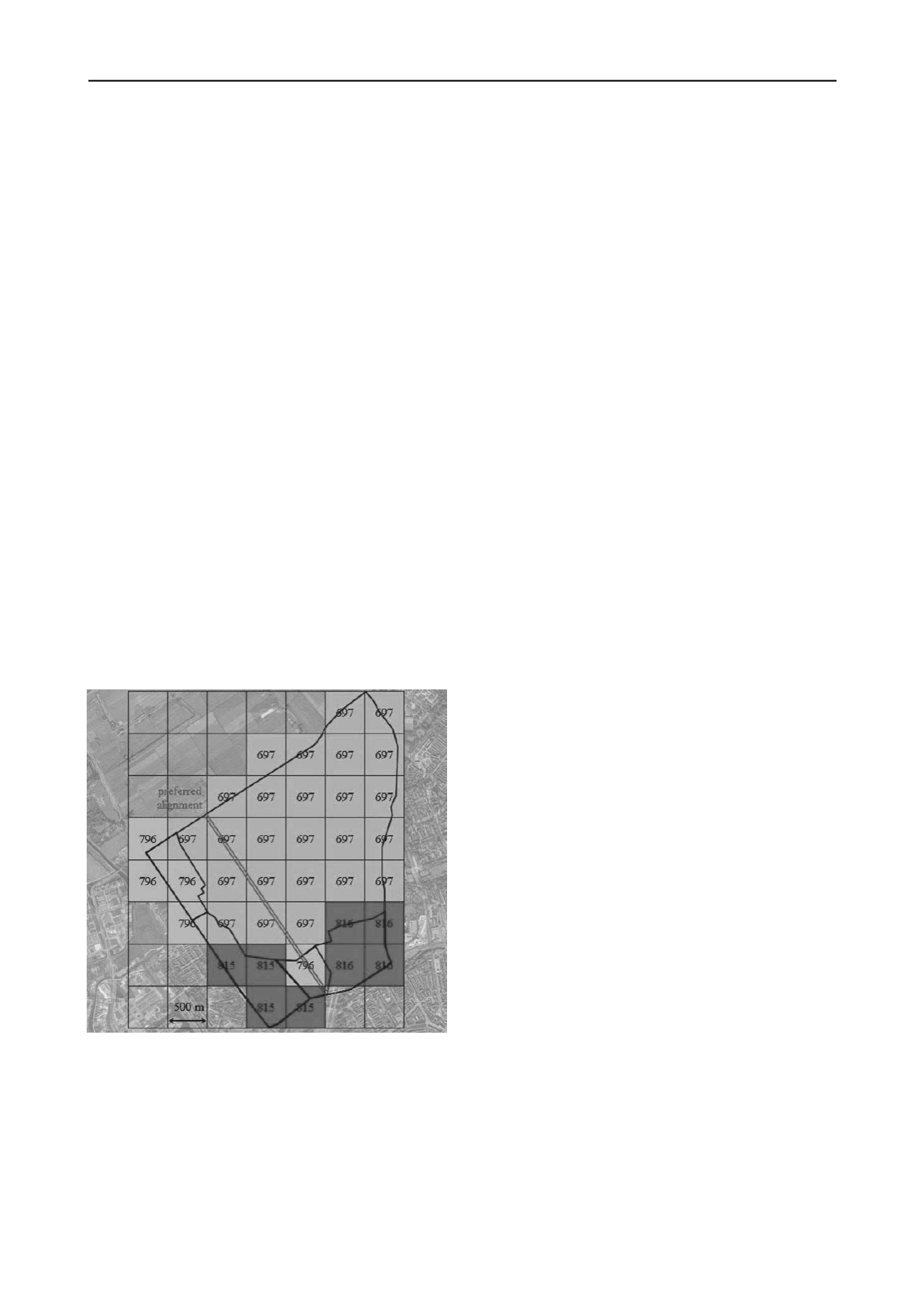

The traditional method with 2 years surcharge time is the

preferred construction method, based on the 90% upper limit of

the whole life costs. The costs of 500 m road are visualised on a

500x500 m

2

grid in Figure 4. The figure also shows the location

of the north-south alignment with the lowest costs. The piled

embankment method will be preferred if the time available for

construction is ½ year or 1 year. The traditional method with 1

year surcharge time is not eligible because of the excessive

uncertainty in the costs.

The design calculations are performed as in the earlier

phases, for a surcharge time of 1 year. The settlements are 10%

higher than in the initial calculations, the post-construction

settlements are compatible. However, the uncertainty in the

post-construction settlements was reduced from 0.17 m in the

initial calculations to 0.02 m. This is caused by the significantly

higher consolidation coefficients. Consolidation is completed

well within the surcharge time of 1 year in all soil profiles, with

only a small amount of creep compression occurring after

construction. The favourable parameters also allowed a

reduction of surcharge height from 2.50 m to 1.50 m, thus

reducing construction cost.

The average whole life costs for 500 m road are 523 k€, a

7% cost reduction as compared to the initial calculations for

subarea III. The 90% upper limit is 560 k€, representing an

uncertainty in the whole life costs of 7% only.

Based on these results, the traditional construction method

with 1 year surcharge time is the best option for area III.

3 CONCLUSIONS AND RECOMMENDATIONS

The example shows that application of the ‘Building with the

Subsurface’ concept in a Value Engineering study is successful.

The concept can identify construction methods that fulfil all

requirements, achieve cost savings, and increase the reliability

of cost estimates. The method for subsoil modelling on the basis

of synthetic soil profiles can successfully quantify heterogeneity

using the conventional tools of geotechnical engineers.

The uncertainty in cost estimates mainly depends on

uncertainty in soil parameters and the sensitivity of the

construction method to these uncertainties. The cost estimate

appears to depend less on lithological heterogeneity. A data

density of 10 verticals/km

2

appears to be sufficient to reduce

uncertainty in cost estimates for the traditional construction

method, even though lithological heterogeneity in the

Rotterdam Airport is high.

Value Engineering studies should include at least one target

parameter related to the uncertainty in cost estimates, rather

than focus on average cost only.

A general data set of compression and consolidation

parameters should be established by systematically collecting

laboratory and field observations, to reduce uncertainty in

geotechnical parameters for feasibility studies.

Figure 4. Whole life costs per 500x500 m

2

grid cell and preferred

alignment of road.

2.8

Local site investigation

The project manager decides to perform an additional site

investigation along the alignment shown in figure 4, aiming to

reduce the uncertainty in the whole life costs of the traditional

construction method with 1 year surcharge time. The site

investigation is targeted at reducing the uncertainty in

compression parameters and consolidation coefficient. The

costs of the site investigation campaign are very modest

compared to saving 1 year in construction time.

4 REFERENCES

Baynes F.J, Fookes P.G., Kennedy J.F. 2005. The total engineering

geology approach applied to railways in the Pilbara, Western

Australia.

Bull Eng Geol Environ

64: 67–94

Van Staveren M.Th. 2006. Uncertainty and ground conditions: a risk

management approach. Elsevier Publishers, Oxford.

Venmans A.A.M., Förster U., Hooimeijer R.H. 2005. Integral design of

motorways on soft soil on the basis of whole life costs. Proc. 16th

ICSMFE Osaka. Balkema, Rotterdam

U.S. DoT Federal Highway Administration 2011. Value engineering.

/