1107

Technical Committee 106 /

Comité technique 106

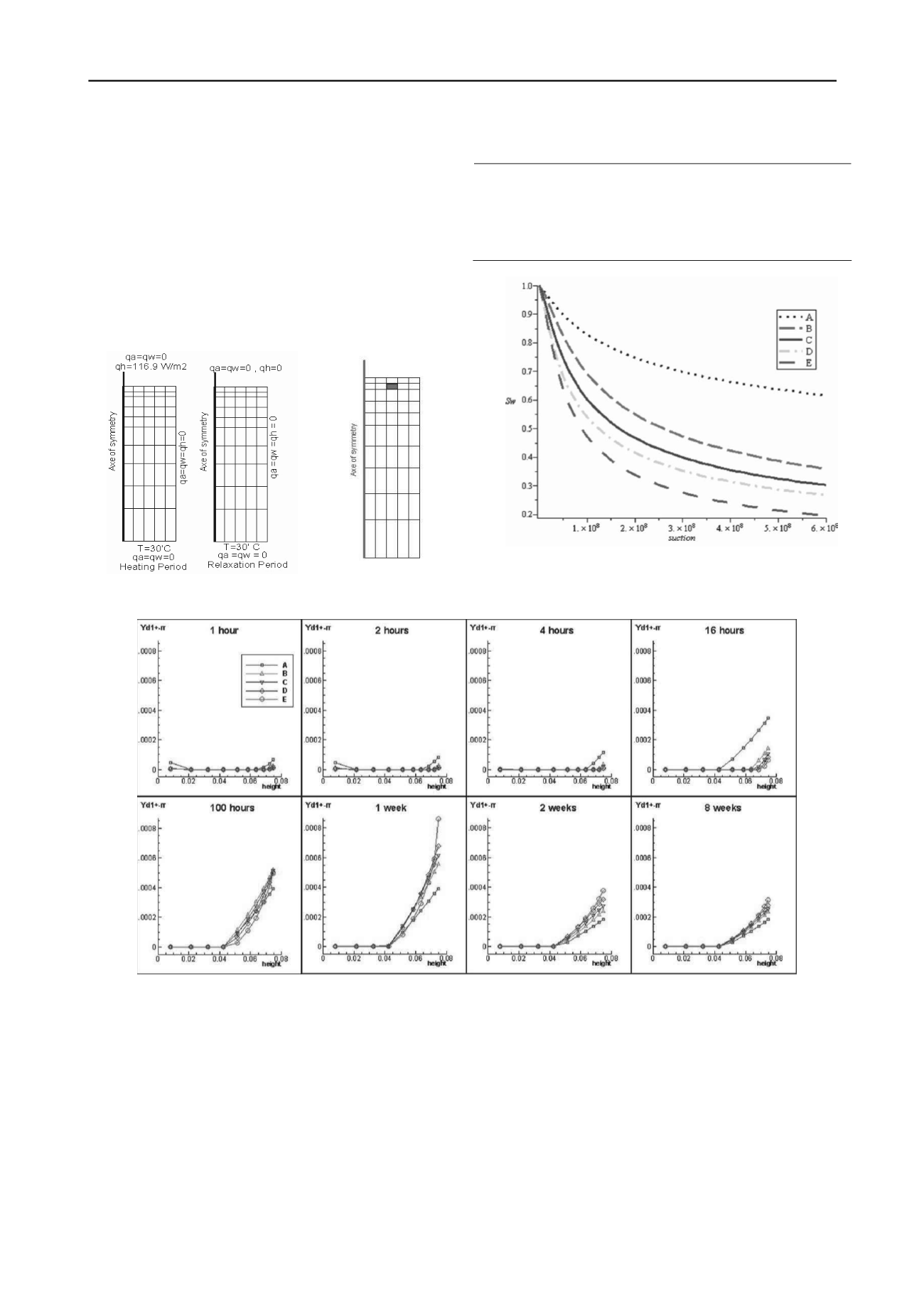

magnitude of damage force in a specific height decreases in

comparison with the previous time.

Table 1. Parameters of the five Van Genuchten water retention

curves

This is because the damage is affected by different parameters:

In one side, heating changes stress distribution which is the

generator of damage; in the other hand, there is extraction of

solid skeleton at the zones near the thermal source, and there is

contraction of it at the further zones, which leads closure of

openings and reducing of generated stresses. Further, the

suction increase is equivalent to a compressive loading, since it

diminishes damage stresses. Therefore, we can say that at first,

factors generating damage forces induce cracks; afterward, in

the following times damage force reduction factors beget to

drop damage force which has been produced at former times.

Graph α(VG) n (VG)

A 1.87E+08 1.2

B 1.87E+08 1.429

C 2.87E+08 1.429

D 3.87E+08 1.429

E 3.87E+08 1.5

Figure 1. Bentonite heating test. Boundary

conditions.

Figure 2. Element

number 22

Figure 3. Five used Van Genuchten water retention curves

Figure 4. Evaluation of damage in all specimens at the whole testing time

Though the heat source is shut down at the time of one week,

the magnitude of damage at the height of about 0.0585 to

0.0665 meters above the bottom of samples is increased at

second week in comparison with one week. The increase of

damage in mentioned part of the sample even after shutting

down the heat source can be discuss as below: It explained

before that in the loading phase, there is extraction of solid

skeleton at the zones near the thermal source, and there is

contraction of it at the further zones. After removing thermal

loading, the distribution of temperature in all elements of upper

part of sample has got relatively uniform; therefore, the zones

with extraction of skeleton get smaller, also the zones with

contraction of skeleton extract. The extraction of this part

causes the pores get bigger and so that the crack opening rises in

this part.

Figure 5, illustrates the damage parameter versus

temperature for an element which is located near the heat source

(element number 22 which is shown in Figure 2). The samples

can be divided into two upside part and downside parts, and the

trends of drying or wetting are investigated. With this strategy,

during the heating period the upside part of the sample loses its

water while the downside part of the sample gets wetter. At the

top part of the samples, using the water retention curves shown

in Figure 3, it can be concluded that specimen E has the highest

amount of moisture and samples D, C, B, A, respectively get

drier. Since the chosen element is in up part of the sample,

according the above arguments, the specimen A is the drier