1036

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Table 2. Test cases and degree of compaction.

For the compaction properties, a series of compaction test were

conducted and maximum dry density of 1.90 t/m

3

and the

optimum water content of 12.3 % were obtained.

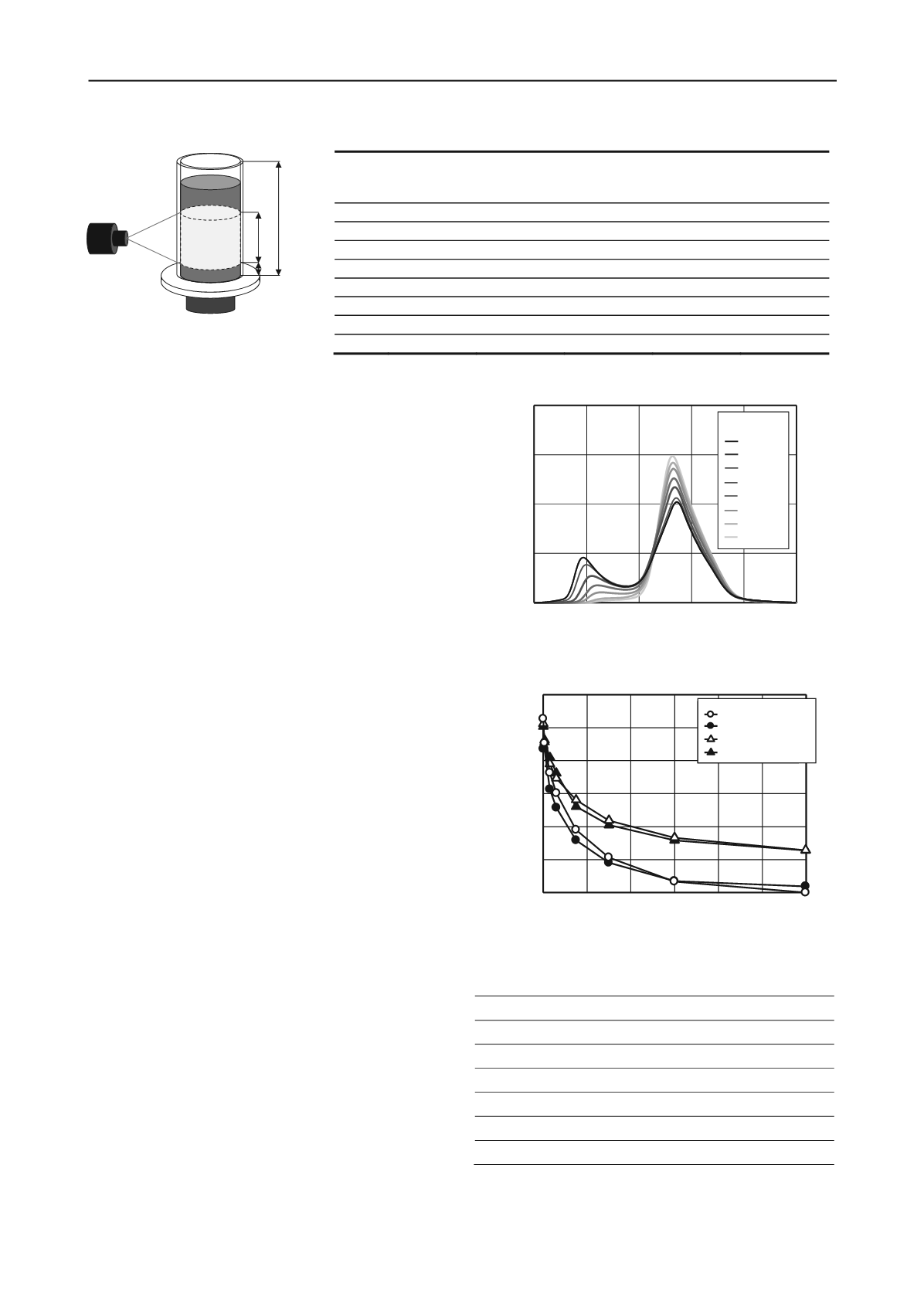

First of all, the sand was prepared in the acrylic mould

(height: 100mm, diameter: 50mm) with the conditions of the

optimum water contents and dry density of 1.50 t/m

3

. Dynamic

compaction method was used with controlling its compaction

energy and here, as shown in Table 2, two different cases were

examined, which are Case-1 and Case-2. Case-1 is the case of

relatively high energy in which the height of each time of

falling rammer is 0.20 m while Case-2 is the one for low energy

which is 0.10m for the falling weight. The weight of falling

rammer was 9.81 N. Figure 2 shows those two cases in which

the level of compaction is also shown in this figure. As shown

in this figure, the amount of work was set as equal for both

cases in each level of compaction although the degree of the

compaction was slightly different between two cases. Table 3

shows the conditions of CT scanning and Figure 2 shows the

scanning area of the specimen, which was the area from 15 mm

high and up to 55mm from the bottom of the specimen and the

width of scanning area was 40mm. The precise contents of X-

ray CT can be found in the references (Otani 2003 and

Watanabe et. al. 2012).

3 IMAGE ANALYSIS

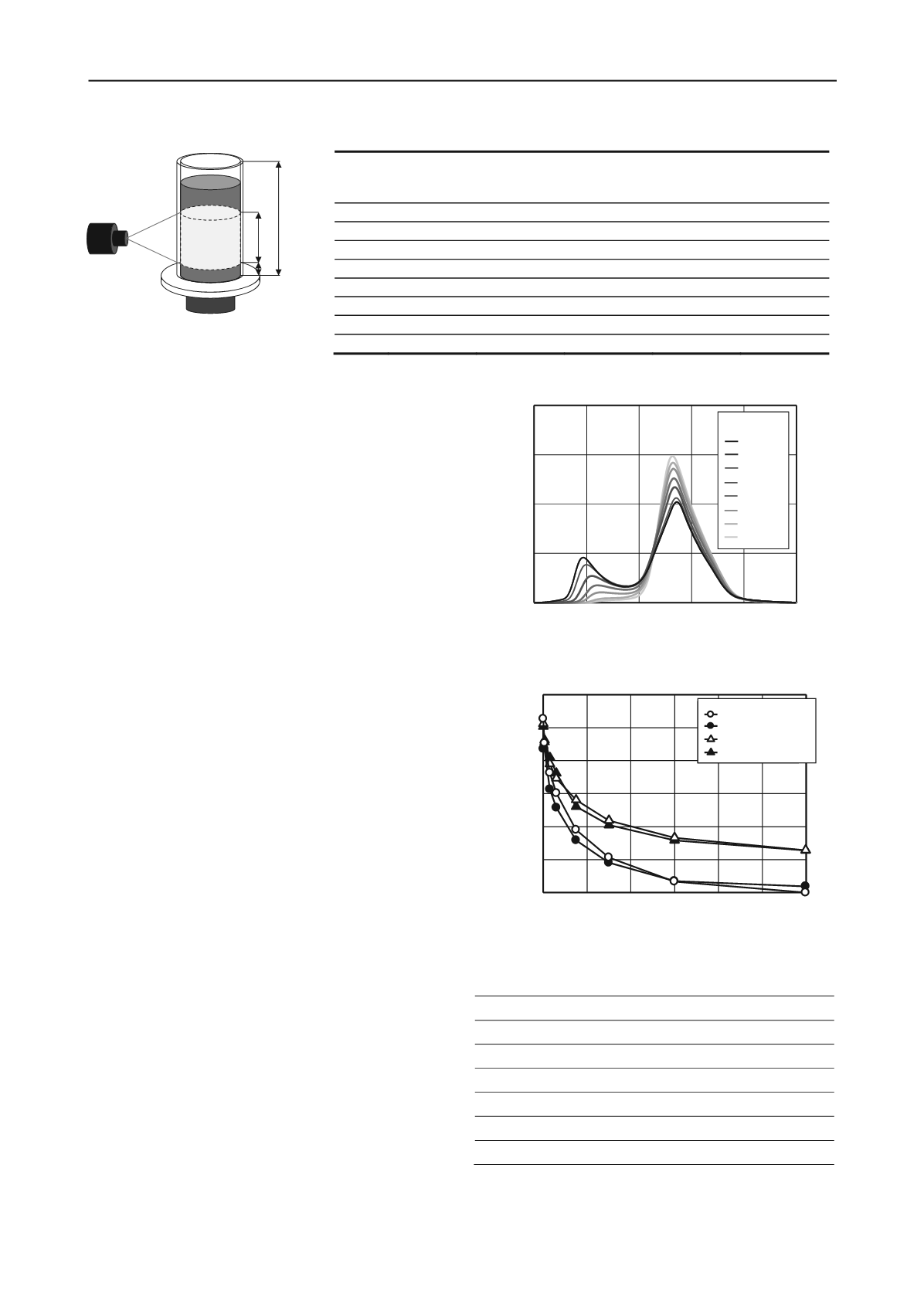

The characteristic of compacted soils was discussed with the

results of CT scanning and those are not only direct result from

image visualization but also more quantitative ones such as

distribution of the voids in the soil using image data. In order to

obtain quantitative results, image analysis plays an important

role and especially, the determination of the threshold value

between two materials such as soil particles and voids is most

important for this quantification. Figure 3 shows the frequency

of so called “CT-value” in the whole specimen for Case-1. This

“CT-value” has been known as the well correlated value with

material density (Otani et. al. 2000). As shown in this figure,

there are two dominant CT-values in the specimen and due to

the level of compaction, those peaks are gradually changed. X-

ray CT has a spatial resolution and in this case, this resolution

was 75

m. The sand used in this test has a fine fraction (less

than 5

m) of 8.2% and as a result, there is no way to

distinguish all the sizes of the particles. However, it can be said

from Figure 3 that the higher peak moves to the higher

frequency and the lower peak moves to the lower frequency

after the compaction. This means that the increase of the CT-

value due to compaction is the cause of the fact that the small

particles move to the voids and then those areas are shown as

the areas of higher CT-values. In the mean time, the area of low

density is decreased due to the decrease of the voids. In order to

discuss more quantitative sense, the threshold value of two

peaks shown in Figure 3 was determined. Here, EM algorithm

(Dempster et. al. 1977) which is one of the maximum likelihood

methods was used and this method is useful for the case of

multiple peaks of the frequency curve. Here, the calculation

Compaction

Energy

(kJ/m

3

)

Case-1

No. of

Compaction

Case-1

Deg. of

Compaction

(%)

Case-2

No. of

Compaction

Case-2

Deg. of

Compaction

(%)

Initital

0

0

79.4

0

78.3

LevelA

15

1

83.3

2

81.3

LevelB

75

5

88.2

10

84.7

LevelC

150

10

91.5

20

87.1

LevelD

374

25

97.5

50

90.6

LevelE

749

50

102.0

100

93.8

LevelF

1497

100

106.0

200

96.5

LevelG

2995

200

109.3

400

98.5

Figure 2. Area of CT scanning.

Scan area

(mm)

100

40 15

500 1000 1500 2000 2500 3000

5

10

15

20

25

30

0

Compaction energy (kJ/m 3 )

Porosity (%)

Case-1 measure

Case-1 analysis

Case-2 measure

Case-2 analysis

Voltage (kV)

200-230

Current

A)

350

Spatial resolution (mm)

0.075

Width of slice (mm)

0.050

Number of slices

800

FCD* (mm)

205.0

FDD** (mm)

1000

*: distance from X-ray tube to the specimen

**: distance from the specimen to the detector

Table 3. Condition of CT scanning.

Figure 4. Relationship between porosity and compaction energy.

Figure 3. Frequency of CT-value for Case-1.

0

50

100

150

200

8

250

0

2

4

6

Case-1

initial

Level A

Level B

Level C

Level D

Level E

Level F

Level G

(

×

106)

Frequency

CT-value