60

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Pender 2000, Kawashima et al. 2007, Chatzigogos et al. 2009;

Panagiotidou et al. 2012]. Applying the methodology which has

been outlined in Gelagoti et al. 2012, the footings were designed

to be adequately small to promote uplifting, but large enough to

limit the settlements. Aiming to minimize differential

settlements stemming from asymmetry, the three footings were

dimensioned in such a manner so as to have the same

F

S

. Based

on the above criteria, the resulting footing widths for the

rocking–isolated design alternative are

B

= 1.1 m, 1.8 m, and

1.3 m, for the left, middle, and right footing, respectively:

indeed, substantially smaller than those of the code-based

design. Footing dimensions and static factors of safety against

vertical loading of the two designs are summarized in Table 1.

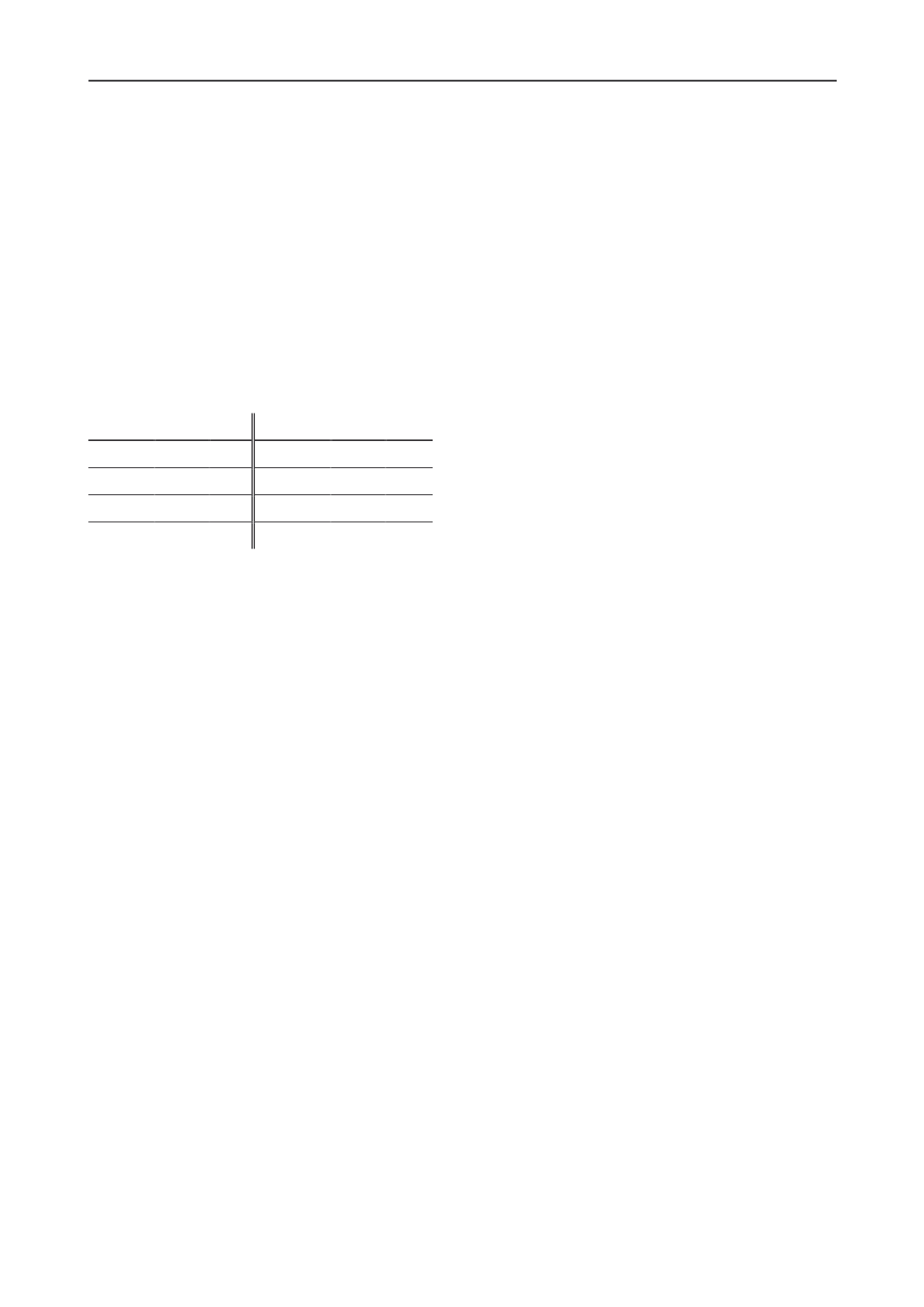

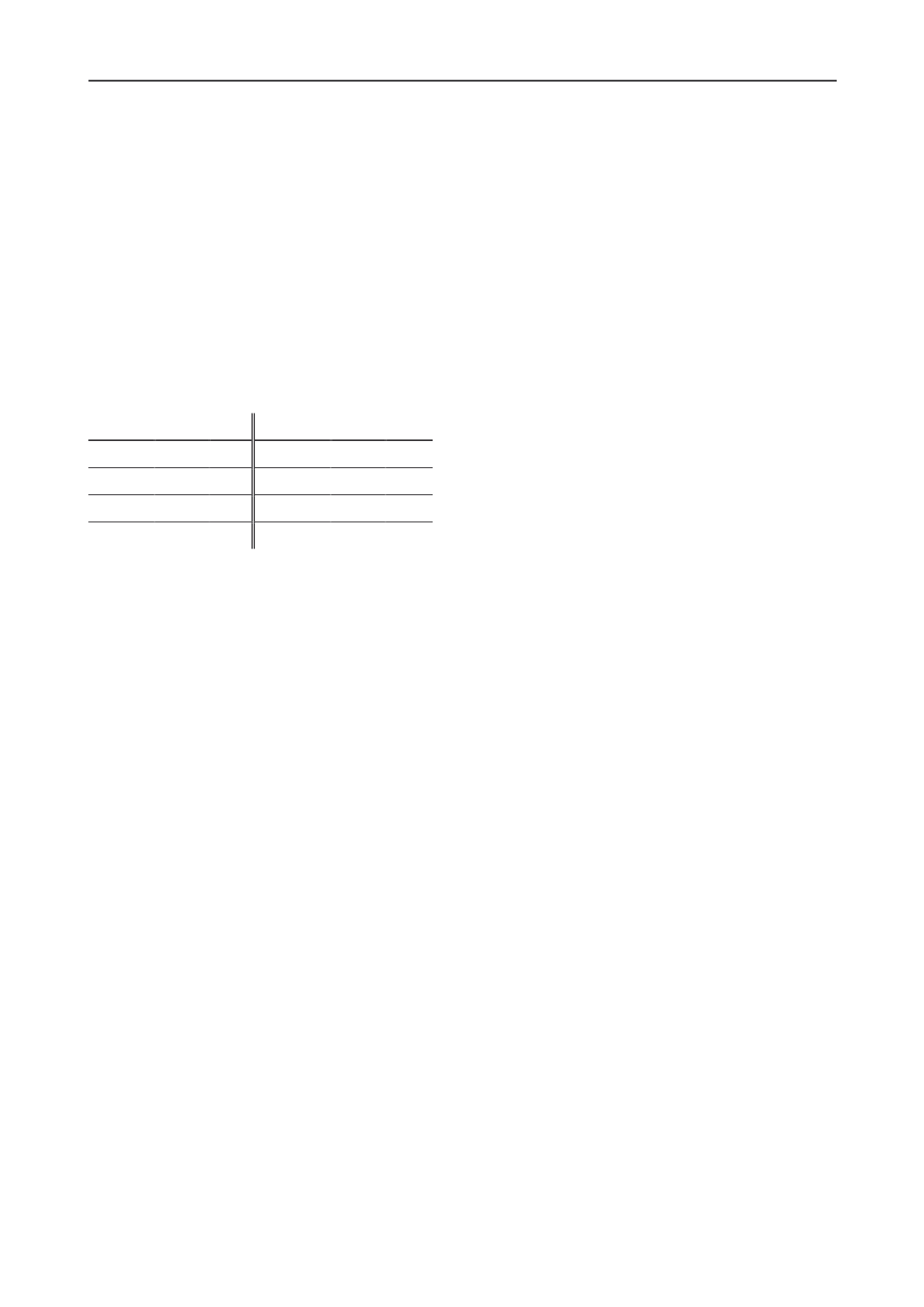

Table 1. Footing dimensions and corresponding factors of safety

(computed following the provisions of EC8) against vertical loading for

the seismic load combination (

G

+ 0.3

Q

) for the two design alternatives

of Fig. 6.

Conventional Design

Rocking Isolation

Footing

B (m)

F

S

Footing

B (m)

F

S

Left

2.7

32.6 Left

1.1

5.4

Middle

2.5

10.6 Middle

1.8

5.4

Right

2.4

18.1 Right

1.3

5.4

The performance of the two design alternatives is compared

in Fig. 6. The deformed mesh with superimposed plastic strain

contours of the two alternatives is portrayed on top

(Fig. 6a).

With the relentless seismic shaking of the Takatori motion, the

conventionally designed frame collapses under its gravity load

(due to excessive drift of the structure, the moments produced

by

P–

δ

effects cannot be sustained by the columns, leading to

loss of stability and total collapse). As expected, plastic hinges

firstly develop in the beams and subsequently at the base of the

three columns, while soil under the footings remains practically

elastic. The collapse is also evidenced by the substantial

exceedance of the available curvature ductility of the columns

(

Fig. 6b). Conversely, the rocking–isolated frame withstands the

shaking, with plastic hinging taking place only in the beams,

leaving the columns almost unscathed (moment-curvature

response: elastic). Instead, plastic hinging now develops within

the underlying soil in the form of extended soil plastification

(indicated by the red regions under the foundation. The time

histories of inter-storey drift further elucidate the

aforementioned behavior of the two design alternatives

(

Fig.

6d).

Thanks to the larger bending moment capacity of the column

than of the footing, damage is guided “below ground” and at the

soil–foundation interface in the form of detachment and

uplifting

evidenced in

Fig. 6d

by the zero residual rotation,

unveiling the re-centering capability of the under-designed

foundation scheme.

The price to pay: large accumulated settlements. Moreover,

despite the fact that the three footings have been dimensioned to

have the same static factor of safety

F

S

(in an attempt to

minimize differential settlements exacerbated from asymmetry),

the central footing settles more than the two side footings,

leading to a differential settlement of the order of 3 cm. The

difference in the settlement stems of course from their

differences in width. As previously discussed, the central

footing was made larger (

B

= 1.8 m, compared to 1.1 m and 1.3

m of the two side footings) in order to maintain the same

F

S

.

Since the latter is common for the three footings, if the loading

is more-or-less the same, their response should be similar.

However, such equivalence refers to dimensionless quantities,

not absolute values [see Kourkoulis et al., 2012b]. In other

words, while the three footings sustain almost the same

dimensionless settlement

w/B

, which is roughly equal to 0.025

(

≈

3 cm/1.2 m) for the two side footings and 0.033 (

≈

6 cm/1.8

m) for the central one, the latter is substantially larger in width

and hence its settlement is larger in absolute terms. Naturally,

the three footings are not subjected to exactly the same loading,

something which further complicates the response. Such

differential settlements may inflict additional distress in the

superstructure, and are therefore worthy of further investigation.

9 THREE

−

STOREY FRAME RETROFITTED WITH

SHEAR

−

WALL

The results presented now are not from numerical analysis as

the previous one, but from Shaking Table experiments. They

refer to a 3-storey two-bay frame which was designed according

to the pre-1970 seismic regulations, for a base shear coefficient

of 0.06. Because of the small value of this coefficient and the

otherwise inadequate design, the frame has columns of cross-

section 25 x 25 cm

2

and beams 25 x 50 cm

2

resulting in a strong

beam

−

weak column system. Naturally, it fails by first “soft-

story” type of collapse when excited by motions corresponding

to today’s codes with effective ground accelerations of the order

of 0.30g and more. To upgrade the frame, a strong and stiff

Shear Wall 1.5 m x 0.3 m in cross-section is constructed

replacing the middle column, as shown in Fig. 7.

The 1:10

−

scale model is supported on dense fine

−

grained D

r

≈

80% sand. The original footings of all three columns were 1.5

m square. For the retrofitted frame the two columns retained

their original 1.5 x 1.5m

2

footings. The foundation of the Shear

Wall (SW) is of special geotechnical interest : due to its

disproportionately large lateral stiffness the SW tends to attract

most of the seismically induced shear force and hence to

transmit onto the foundation a large overturning moment. By

contrast, its vertical load is relatively small. To meet the

eccentricity limit e = M/N < B/3, a large foundation 6.0m x 0.80

m is thus necessary. Hence, the conventional solution of Fig. 8.

Of course the resulting vertical bearing-capacity factor of safety

is unavoidably large, F

S

≅

10, and the seismic apparent factor of

safety against moment bearing-capacity is also far more than

adequate :

F

E

= 2.

The decision to reduce the footing width to merely B = 3.5 m

is not only economically favorable, but in the harsh reality of

old buildings it may often be the only feasible decision in view

of the usual space limitations due to pipes, small basements,

walls, etc, present in the base. We will see if it is also favorable

technically in resisting a strong seismic shaking.

To be practical, in the above sense, no change is made to the

column footings. (1.5 m square).

We subject all three structures [ i.e., “a” the original frame,

“b” the retrofitted with a SW founded on conventionally-

conservative footing, and “c” the retrofitted with the

underdesigned SW footing] to a number of strong ground

excitations. Frame “a” easily fails as sketched in

Fig. 8,

where

the physical collapse was artificially prevented by an external

protective barrier in the Shaking Table experiment. The

conventionally retrofitted SW-frame “b” could withstand most

excitations. But with some of the strongest motions it developed

substantial plastification at its base and led to residual top drift

of an unacceptable 8%.

The unconventionally–founded system “c” behaved much

better with residual top drift of merely 2%.

Figure 8 sketches the deformation pattern of the three

systems while Fig. 7 plots the time histories of

structural

−

distortion and foundation

−

rotation induced top drift

ratio. It is seen that not only is the total drift of the Rocking-

Isolated system only 2% but at least half of it is solely due to

foundation rotation, rather than damage to the SW.

The penalty to pay is the increased settlement (1.5 cm rather

0.8 cm) which nevertheless in this particular case would be

acceptable for most applications.