1794

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

SP1

SP2

SP3

SP4

SP5

SP6

SP7

2.5

2.5

3+100

EAST

PORTAL

SP8

SP9

SP10

SP11

SP12

SP13

SP14

SP15

SP19

SP20

SP21

SP22

SP23

SP25

SP26

SP27

SP28

Figure 1. Plan of Niayesh east portal - north tunnel

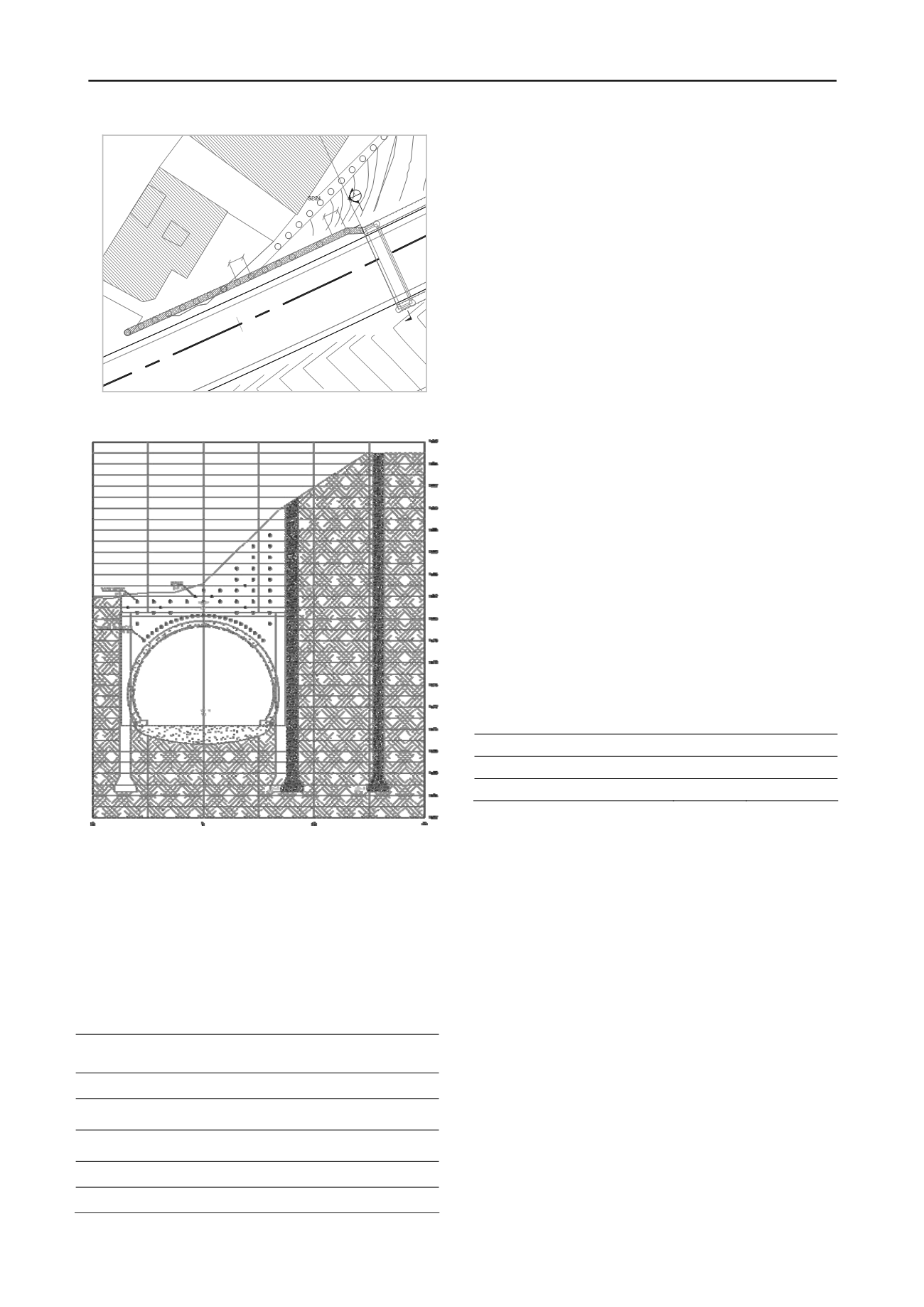

Figure 2. Section A-A, (see Figure 1)

Based on the field and the laboratory test results, subsurface

conditions are described as follows:

Generally, filling material can be found to El. +1480 that is

about 2 meter above tunnel. Beneath the filling soil layer, soil

profile is composed of dense sandy gravels and dense clayey

gravels, both contains silt and clay material. Table 1 shows the

geotechnical properties of different soil materials.

Table 1.Geotechnical parameters of different layers

Elevation

To +1480

+1480 to

+1475

Under

+1475

Cohesion (kg/cm

2

)

0.1

0.2

0.3

Poisson Ratio ν

0.32

0.3

0.3

Frictional Angle (·)

35

35

35

Natural density (gr/cm

3

)

1.8

1.9

1.9

Young’s Modulus (kg/cm

2

)

600

650

650

3 NUMERICAL ANALYSES

3.1 Softwares

Numerical analyses have performed by 3D finite element

software released by Plaxis company. Plaxis3D Tunnel is a

finite element package specifically intended respectively for the

analysis of deformation and stability in tunnel projects.

The NATM construction progress were modelled by stepped

construction phases. In the applied performance method, after

excavation of each stages, a 15 cm reinforced shotcrete layer,

supported with lattice elements, will cover the excavated

surface as an initial lining. The well-known Hardening-Soil

model (Schanz et al. 1999) was used to model the soil layers.

3.2

Input parameters

Regarding 3 dimensional tools, Plaxis3D Tunnel can be used to

analyze some non-planar problems. Therefore, eastern portal of

the north tunnel is modelled by Plaxis3D Tunnel.

Construction stages are simulated in analyses and

geometry of slope and material parameters were considered

similar to analysis conditions described below.

The soil parameters assigned as presented in table 1. Soil

nails and forepoles are modelled by geogrid elements and initial

lining elements are modelled by plate elements. Geogrids are

with normal stiffness but no bending stiffness. They can only

sustain tensile force and no compression and plates are

structural elements with bending and axial stiffness. The most

important parameters of plates are flexural rigidity (bending

stiffness) EI and axial stiffness EA.

Character of all the plate elements used as a interior

temporary beam element which removed during the

construction stages applied as internal lattice that presented in

table 2 and characters of all of the plate elements used to model

initial lining of the tunnel, including 15 cm reinforced shotcrete

and steel lattices, applied as external lattice.

Table 2.Structural element properties

Element

EA (KN/m)

EI (KN.m

2

/m)

Internal lattice

5.3E6

1.4E4

External lattice

7.4E6

3.8E4

In this section, the results of the short-term stability and

performance analysis of the north tunnel under the reinforced

slop are presented. The model geometry was established

according to the project specifications. Considering the adjacent

buildings, the distributed load of 6000 kg/m2 is applied and

2000 kg/m2is applied for the highway that abuts under the slop.

At the location of the portal, the north tunnel will be

constructed in minimum depth of 7 m under toe of the

reinforced slop. Regarding the stages of the construction of the

tunnel, the staged construction applied in the numerical

modelling.

In staged construction right top and bottom drifts, as it is

shown in figure 3, are removed after left top and bottom drifts,

respectively. All the stages are followed by placing initial lining

elements on excavated soil face.

It should be noted that in the 3D model the portal is

excavated before tunnel construction.