1401

Technical Committee 203 /

Comité technique 203

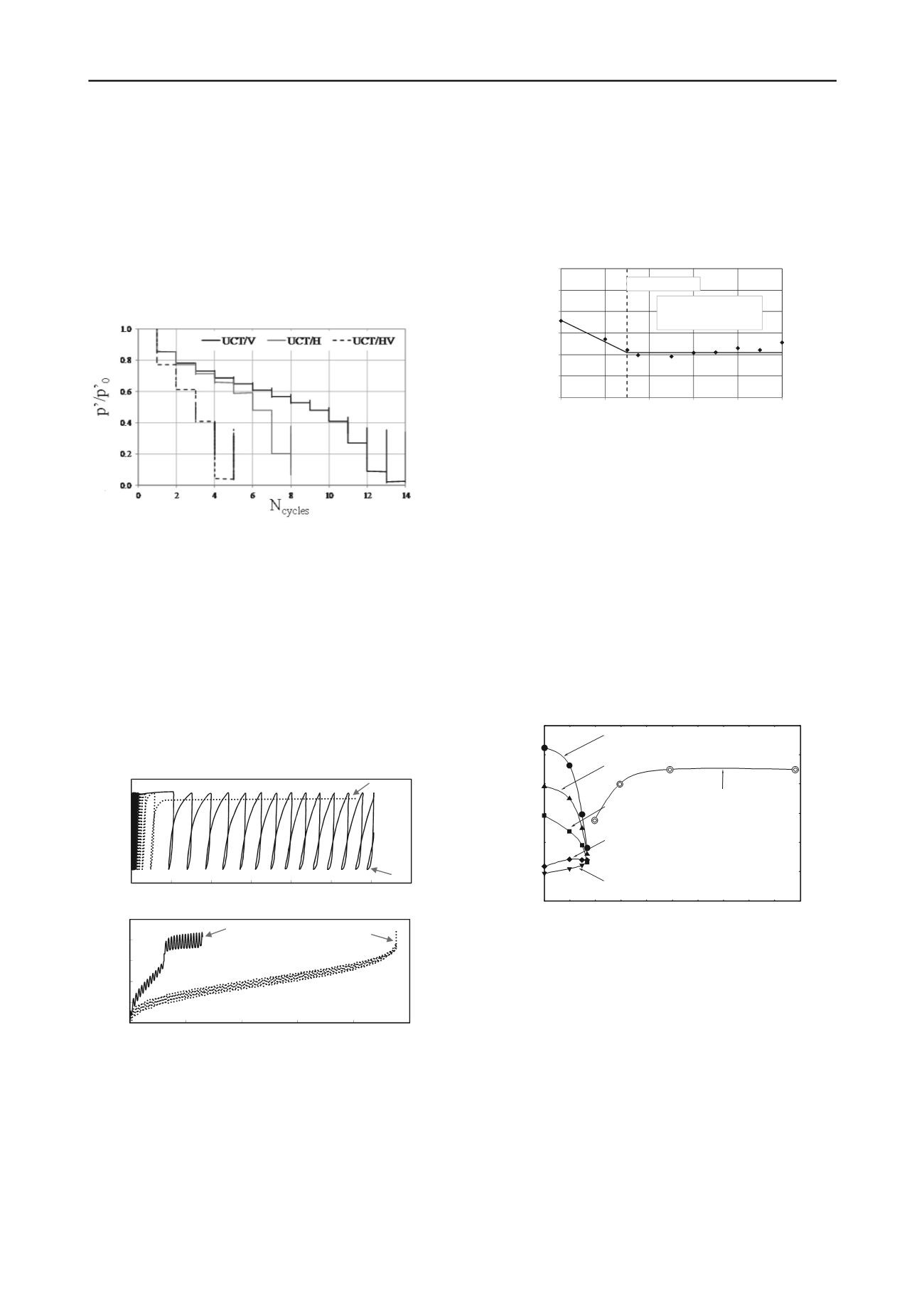

UK), in their ‘Challenges to the laboratory evaluation of field

liquefaction resistance’. Air-pluviated specimens of uniform

Coimbra sand were saturated, isotropically consolidated at the

same effective stress, and subjected to undrained CTX tests with

different loading patterns. Irregular axial loads including a

singular higher amplitude cycle pointed out the significant

influence of its location, in terms of current mean effective

stress ratio, p’/p’

0

, on the number of cycles for the onset of

liquefaction. Cyclic strength was greater under axial (UCT/V)

than under radial (UCT/H) loading; also, multidirectional load

patterns (UCT/HV) led to an even faster degradation than that

observed in the unidirectional tests (Fig. 6).

Figure 6. Comparison between liquefaction resistance under

unidirectional and multidirectional loading (

Coelho et al.

).

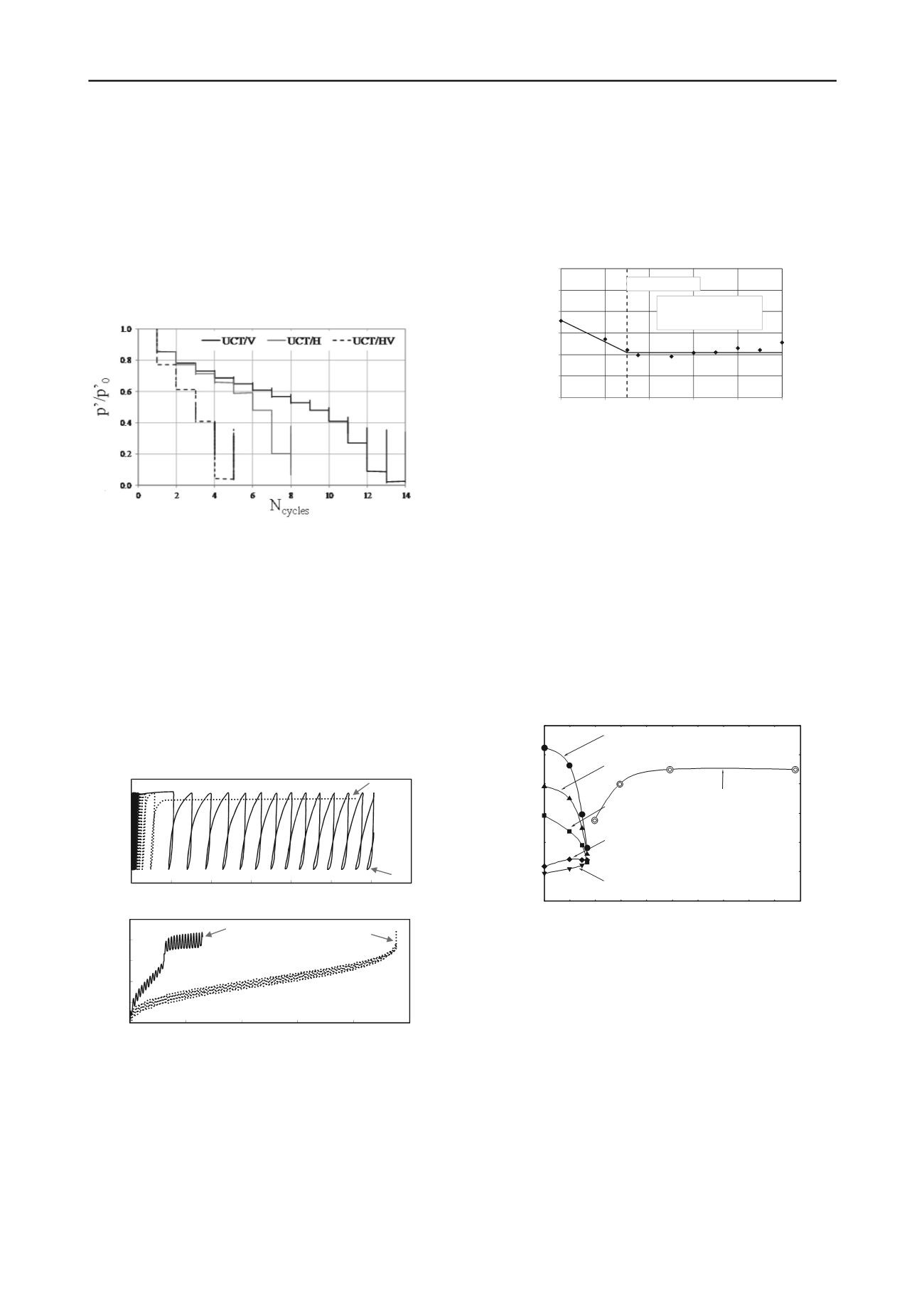

Sze & Yang

(Hong Kong) studied the ‘Cyclic loading

behavior of saturated sand with different fabrics’ by comparing

the failure modes of moist tamped (MT) and dry deposited (DD)

loose specimens of uniform Toyoura sand. Undrained CTX tests

were driven with different static shear stress ratio,

, showing

different failure modes, varying from ‘cyclic mobility’ to

‘limited’ or ‘runaway’ deformation (Fig. 7). The mechanisms

are viewed as dependent on both inherent anisotropy (expected

to be higher for DD specimens) and the stress-induced fabric

changes, in turn controlled by the combination between

and

the cyclic stress ratio, CSR=q

cyc

/(

1c

+

3c

). The Authors

conclude that fabric effects might be very significant, although

they are inherently not accounted for in conventional design

procedures, such as those based on liquefaction charts.

-50

0

50

100

150

200

250

0

2

4

6

8

10

12

1

Deviatoric stress (kPa)

Axial strain (%)

MT

DD

4

0

100

200

300

400

500

0

20

40

60

80

1

Excess PWP (kPa)

Loading cycles

MT

DD

00

Figure 7. Limited (DD) vs. runaway (MT) deformation for

=0.1,

CSR=0.11 (

Sze & Yang

).

3.2

Silty sands

Mominul et al.

(Bangladesh) investigate on ‘Dynamic properties

and liquefaction potential of a sandy soil containing silt’ by

means of undrained CTX tests on wet tamped specimens of

dense silty sand. Results are reported in terms of strain

dependent modulus and damping (indeed, well beyond the

linear threshold strain), and cyclic resistance curves relevant to

both pore pressure ratio and strain amplitude criteria are

compared. The ‘cyclic resistance ratio’ (i.e. CRR) was defined

as the CSR value required to reach 5% double amplitude axial

strain in 20 cycles: it was seen to decrease with non-plastic silt

content increasing up to 30%, and to be nearly constant above

this value (Fig. 8). It must be recalled that conventional

empirical methods imply increasing the cyclic resistance ratio

when plastic fines are present, but no correction for non-plastic

fines is normally implemented.

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0

20

40

60

80

1

Cyclic StrengthRatio

LimitingFineContent

00

Silt Content (%)

AxialStrain±3%,at 20Cycles

Effectivestress=100

kPa,Dr=60%,

f =

1Hz

n of cyclic strength ratio with non-plastic silt content

(

M

if a properly

defined ‘equivalent granular void ratio’ is adopted.

Figure 8. Variatio

ominul et al.

).

Noda & Hyodo

(Japan) also investigate on ‘Effects of fines

content on cyclic shear characteristics of sand-clay mixtures’ by

mixing silica sand with a medium plasticity clay in different

proportions, spanning from clean sand to clayey silt. By

comparing undrained CTX tests on specimens compacted with

different energy, it was again observed that the cyclic resistance

ratio decreased with fines content, F

C

, up to about 20% for

dense mixtures, while the opposite trend was shown by the

loose ones (Fig. 9). Specimens with plastic F

C

>20% had to be

prepared by slurry pre-consolidation: they showed a rapid

increase of the cyclic resistance ratio up to F

C

=50%, beyond

which the liquefaction strength asymptotically approached that

of the clayey silt. Finally, the Authors interestingly suggest that

with non-plastic F

C

<20%, the dependency of cyclic resistance

ratio on F

C

at a given relative density is scaled out,

0 10 20 30 40 50 60 70 80 90 100

0.05

0.10

0.15

0.20

0.25

0.30

0.35

Cyclic deviator stress ratio, R

L(N=20)

E

c

=504kJ/m

3

E

c

=324kJ/m

3

E

c

=113kJ/m

3

E

c

=51kJ/m

3

E

c

=22kJ/m

3

Fines content, Fc(%)

Pre-consolidation

method(

σ

v

=50kPa)

n-plastic (F

C

<20%)

and plastic (F >20%) silt content (

Noda & Hyodo

).

th confining

pressure, apparently due to interlocking soil fabric.

Figure 9. Variation of cyclic resistance ratio with no

C

3.3

Peculiar soils

Elmamlouk et al.

(Egypt) analyze the ‘Liquefaction

susceptibility of loose calcareous sand of Northern Coast in

Egypt’ by means of undrained CTX tests on a poorly graded

calcite-sand with apparently non-plastic fines content lower

than 10%. Reconstituted specimens were prepared by tamping,

appropriately using undercompaction technique (Ladd, 1978) to

reach the target relative density D

r

=40% after consolidation.

This calcareous sand showed greater cyclic strength (in terms of

pore pressure ratio r

u

=1.0) compared to siliceous sands at the

same D

r

and

c

(Fig. 10). Particle crushing under cyclic loading

was found to be insignificant for the range of σ′

c

applied,

resulting into a cyclic resistance ratio decreasing wi